Overview of Polyol/Polyether Polyol/Polymer Polyol/Pop for PU Foam

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Polyol/Polyether Polyol/Polymer Polyol/Pop for PU Foam

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

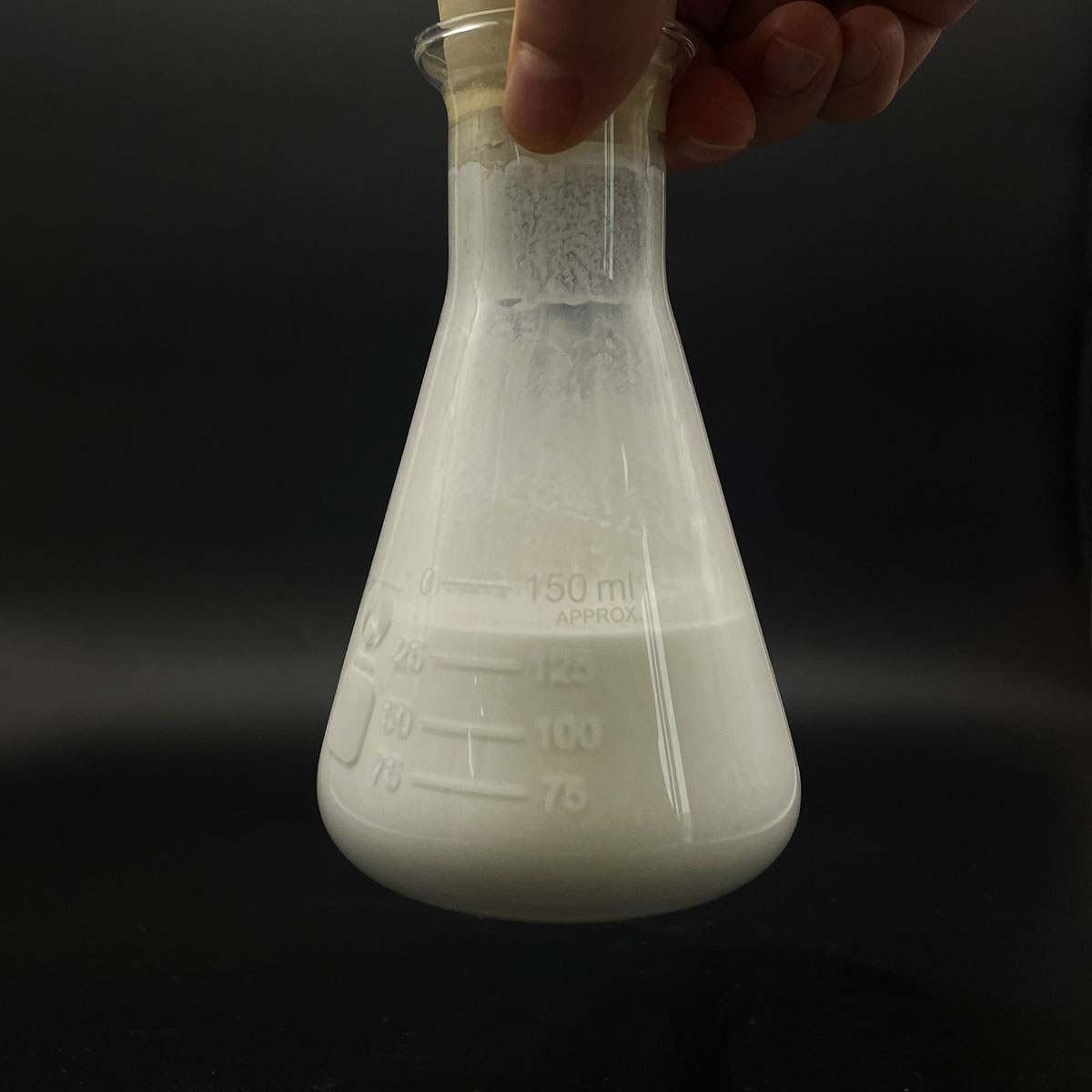

(Polyol/Polyether Polyol/Polymer Polyol/Pop for PU Foam)

Specification of Polyol/Polyether Polyol/Polymer Polyol/Pop for PU Foam

Polyols, including Polyether Polyol, Polymer Polyol (POP), and conventional Polyol, are vital raw materials for generating polyurethane (PU) foam, affecting its thickness, versatility, toughness, and thermal residential or commercial properties. Their requirements figure out reactivity, foam framework, and efficiency in end-use applications.

** Polyol ** functions as the base part, reacting with isocyanates to develop PU. Secret specifications consist of hydroxyl worth (20– 800 mg KOH/g), which influences crosslink thickness and foam hardness. Viscosity (200– 10,000 cP) influences processing simplicity, while capability (2– 8) establishes the polymer network’s branching. Molecular weight (500– 10,000 g/mol) influences foam flexibility, and acid worth (

(Polyol/Polyether Polyol/Polymer Polyol/Pop for PU Foam)

Applications of Polyol/Polyether Polyol/Polymer Polyol/Pop for PU Foam

Polyols, including Polyether Polyols, Polymer Polyols (POP), and various other variations, are fundamental in making polyurethane (PU) foams, which offer varied markets as a result of their versatile homes. These products determine foam features like flexibility, density, and toughness, enabling customized solutions for specific applications.

** Polyether Polyols ** are main to versatile PU foams, prized for their durability and comfort. They are extensively made use of in mattresses, upholstered furnishings, and vehicle seats, where gentleness and durability are crucial. In automobiles, these foams boost seat paddings, headrests, and armrests, adding to noise decrease and vibration dampening. They additionally master packaging and sports floor coverings due to their energy-absorbing homes.

** Polymer Polyols (POP)** improve foam solidity and load-bearing ability without sacrificing adaptability. This makes them excellent for high-resilience furnishings, such as office chairs and couch cores calling for long-lasting assistance. In automotive applications, POP-based foams are made use of in seat paddings and back-rests to sustain regular usage while preserving shape. Footwear benefits from appear midsoles and insoles, mixing cushioning with durability. POP also simplifies production, making it possible for complicated mold and mildew styles and price performance.

** Inflexible PU foams **, created with specialized polyols, supply superior thermal insulation and structural stamina. These foams are vital in construction for insulating wall surfaces, roofs, and pipelines, increasing power efficiency. Refrigeration systems count on stiff foams to keep temperature level consistency, reducing energy usage. Automotive applications include lightweight panels that boost fuel performance by minimizing automobile weight.

Past foams, polyols are crucial in adhesives, sealants, and elastomers. PU adhesives bond materials like plastics and metals, while sealants provide airtight services in construction and automotive assembly. Elastomers derived from polyols are utilized in commercial belts, gaskets, and wheels, supplying abrasion resistance.

Sustainability drives advancement, with bio-based polyols from renewable resources like soybeans getting importance. These green alternatives decrease petroleum reliance and line up with international ecological goals. Flame-retardant polyols additionally improve safety and security, meeting rigorous fire requirements in applications like structure materials and transport.

In summary, polyols allow PU foams to fulfill needs across sectors– from consumer convenience to commercial efficiency. Their adaptability and progressing formulas continue to advance performance and sustainability, strengthening their duty in contemporary manufacturing.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Polyol/Polyether Polyol/Polymer Polyol/Pop for PU Foam

What is Polyol and its role in PU Foam production? Polyol is a key raw material in polyurethane (PU) foam manufacturing, acting as the “soft” segment in the polymer structure. It reacts with isocyanates (the “hard” segment) in a polymerization process to form PU foam. Polyols determine foam properties like flexibility, density, and durability. Common types include polyether and polyester polyols, with polyether variants being widely used for flexible foams due to their cost-effectiveness and hydrolytic stability.

How does Polyether Polyol differ from other polyols? Polyether Polyol is synthesized by polymerizing epoxides (like ethylene or propylene oxide) with initiators containing active hydrogen. It offers superior flexibility, water resistance, and processing ease compared to polyester polyols, which are more rigid and prone to hydrolysis. Polyether polyols are ideal for flexible foams (e.g., mattresses, car seats) due to their resilience and ability to maintain structure under stress.

What is Polymer Polyol (POP) and why is it used in PU Foam? Polymer Polyol (POP) is a modified polyol containing dispersed polymer particles (e.g., styrene-acrylonitrile) within a polyether base. It enhances load-bearing capacity and hardness without compromising comfort, making it essential for high-resilience foams in furniture, automotive interiors, and bedding. POP reduces raw material costs by partially replacing pure polyol while improving mechanical properties.

How do polyol types influence foam density and performance? The molecular weight, hydroxyl value, and functionality of polyols directly impact foam density and performance. Higher hydroxyl values increase crosslinking, leading to firmer foams. Polyether polyols create low-density, flexible foams, while polymer polyols add rigidity. Adjusting the polyol-isocyanate ratio and additives (e.g., catalysts, surfactants) tailors properties like airflow, compression set, and thermal stability.

What are storage and handling precautions for polyols? Polyols must be stored in sealed containers at 20–30°C to prevent moisture absorption, which can cause unwanted reactions. Avoid contamination with water, acids, or amines, as these degrade quality. Use stainless-steel or coated tanks to prevent catalytic effects from metals. Pre-heating viscous polyols (e.g., POP) to 25–35°C ensures smooth processing. Follow safety guidelines to minimize exposure to skin/eyes and ensure proper ventilation.

(Polyol/Polyether Polyol/Polymer Polyol/Pop for PU Foam)