Overview of Pop 25% 45% Polymer Polyol for Polyurethane Flexible Songe Foam

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Pop 25% 45% Polymer Polyol for Polyurethane Flexible Songe Foam

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

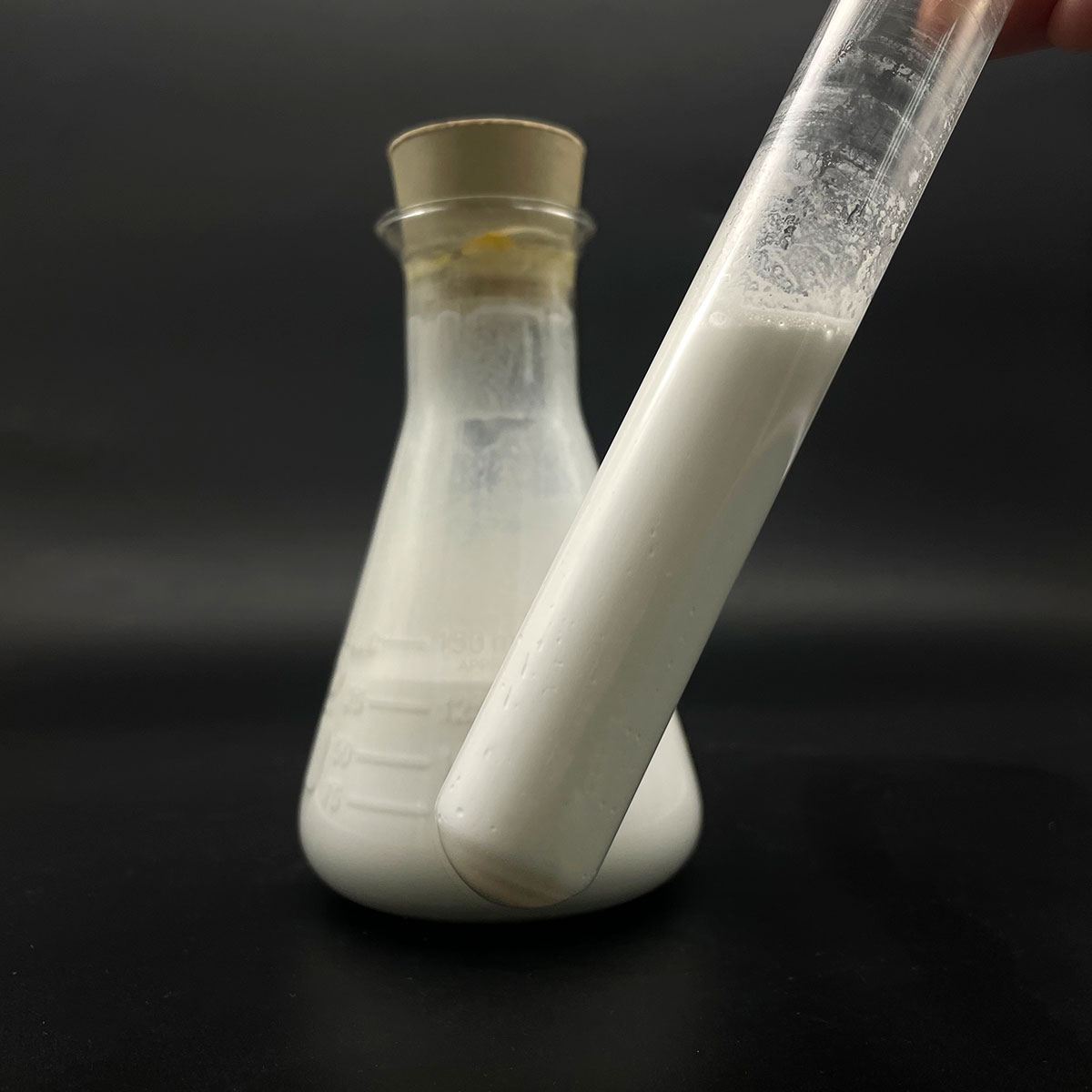

(Pop 25% 45% Polymer Polyol for Polyurethane Flexible Songe Foam)

Specification of Pop 25% 45% Polymer Polyol for Polyurethane Flexible Songe Foam

Pop 25% 45% Polymer Polyol is a specialized product created for producing polyurethane versatile sponge foam. It works as a key element in foam solutions. The item enhances foam physical residential or commercial properties. It enhances load-bearing capacity and sturdiness. This polymer polyol consists of 25% or 45% solids content. The solids are carefully spread in a base polyol. The diffusion makes sure stable performance throughout foam handling.

The product has a hydroxyl worth in between 28-35 mg KOH/g. This range sustains ideal crosslinking throughout responses. Viscosity ranges 3000-6000 mPa · s at 25 ° C. The thickness permits easy handling in blending systems. Water content stays below 0.05%. Low wetness prevents undesirable side responses. The pH value stays neutral. This makes sure compatibility with typical foam active ingredients like isocyanates.

Pop 25% 45% Polymer Polyol functions well in slabstock and shaped foam production. It aids develop foams with consistent cell framework. The foam shows high resilience and gentleness. It reduces shrinking throughout curing. The item supports open-cell development. This boosts air flow in completed foam products.

The polymer polyol raises foam tensile stamina. It enhances resistance to use and contortion. Foams preserve convenience over lasting use. They adapt well to furniture, cushions, and vehicle seats. The material follows industry safety and security standards. It meets demands for flame retardancy and emissions.

Handling calls for common foam production equipment. Mix the polymer polyol with isocyanates, drivers, and blowing representatives. Follow advised ratios for target foam thickness. Readjust temperatures in between 20-30 ° C throughout blending. Cure foam at controlled moisture levels.

Shop Pop 25% 45% Polymer Polyol in covered containers. Avoid dampness and straight heat. Usage within 6 months for finest performance. Check for sedimentation prior to usage. Stir carefully if separation occurs. Stay clear of contact with strong oxidizers. Follow neighborhood disposal regulations for unused material.

(Pop 25% 45% Polymer Polyol for Polyurethane Flexible Songe Foam)

Applications of Pop 25% 45% Polymer Polyol for Polyurethane Flexible Songe Foam

Pop 25% and 45% polymer polyol is a crucial product for making polyurethane flexible sponge foam. This item enhances foam performance in numerous means. It is widely made use of in furniture, automotive seats, cushions, and product packaging. The polymer material (25% or 45%) changes foam residential or commercial properties to fit various demands. Higher polymer levels create stronger foam with better toughness. Lower degrees maintain foam soft while adding strength.

In furnishings manufacturing, this polyol helps develop sofa paddings and chair cushioning. Foam made with it holds form much longer. It resists sagging even after years of use. Automobile producers utilize it for seat pillows and headrests. The foam soaks up resonances during driving. This makes rides extra comfy.

Bed mattress manufacturers take advantage of this polyol. Foam remains helpful yet soft. It adjusts to body weight and shape. Individuals rest much better without pressure factors. Healthcare facilities use such foam for medical bed mattress. It prevents bedsores in individuals that stay in bed lasting.

Product packaging materials made with this polyol shield fragile products. Foam takes in shocks during delivery. Electronic devices and glass products get here intact. The foam is light-weight. This cuts shipping prices compared to larger products.

Shoe manufacturers use it for insoles and midsoles. The foam paddings feet during strolling or running. It lasts longer than standard foams. Professional athletes and workers on their feet throughout the day choose this convenience.

Making foam with Pop polymer polyol conserves money. Factories utilize less basic material without shedding high quality. The process stays efficient. Foam cures much faster in molds. This accelerate production lines.

Custom-made foam blends are possible by adjusting polymer content. A 25% polyol provides softer foam for pillows or luxurious toys. A 45% version works for sturdy usages like fitness center floor covering or industrial extra padding. Both kinds stand up to oil, water, and chemicals. This makes cleansing much easier.

The polyol collaborates with existing foam-making equipment. No significant manufacturing facility changes are needed. Makers switch over solutions conveniently. Examining programs foam meets fire security criteria. It creates much less smoke if exposed to flames.

This material supports environmentally friendly objectives. Some variations use recycled content. Others reduce energy use throughout manufacturing. Waste foam can be recycled right into brand-new items. Business reduced their environmental impact.

Pop polymer polyol remains steady in storage space. It resists dampness and temperature adjustments. Factories maintain it ready for use without unique problems. Worldwide supply chains count on this reliability.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Pop 25% 45% Polymer Polyol for Polyurethane Flexible Songe Foam

Pop 25% 45% Polymer Polyol is a key material for making polyurethane flexible sponge foam. Below are common questions people ask about it.

What is Pop 25% 45% Polymer Polyol?

This polymer-based polyol is used to produce flexible foam. The numbers 25% and 45% show the polymer content. Higher polymer levels improve foam strength and structure.

Why use this polyol instead of regular polyol?

It makes foam more durable. The polymer particles add stiffness without sacrificing softness. This balance is hard to achieve with standard polyols. Production costs stay low because less material is needed for the same performance.

How does it affect foam properties?

Foam made with this polyol has finer cell structures. This improves load-bearing capacity and elasticity. The foam lasts longer under repeated use. It works well for furniture, mattresses, and car seats.

Is it safe to handle during production?

Follow standard safety steps. Wear gloves and goggles. Avoid skin contact. Use in ventilated areas to limit fumes. Check the safety data sheet for specific handling guidelines.

How should it be stored?

Keep containers sealed tightly. Store in a dry, cool place away from sunlight. Moisture can ruin the product. Use within six months for best results. Rotate stock to avoid old batches.

These answers cover basics about Pop 25% 45% Polymer Polyol. Users should test the product in their specific applications to confirm performance.

(Pop 25% 45% Polymer Polyol for Polyurethane Flexible Songe Foam)