Overview of Asphalt Emulsifier for Anionic Bitumen Emulsion RS-1

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Asphalt Emulsifier for Anionic Bitumen Emulsion RS-1

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

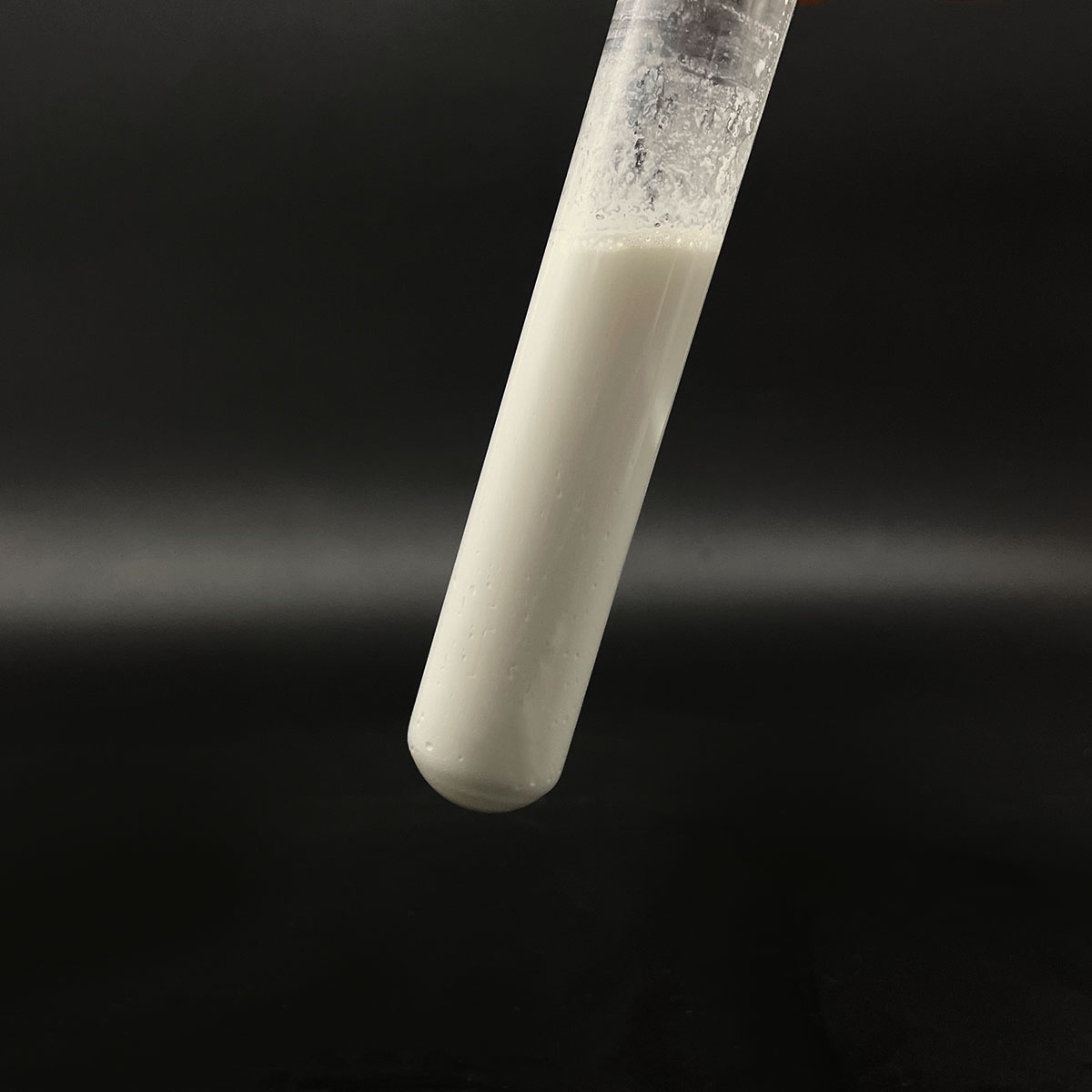

(Asphalt Emulsifier for Anionic Bitumen Emulsion RS-1)

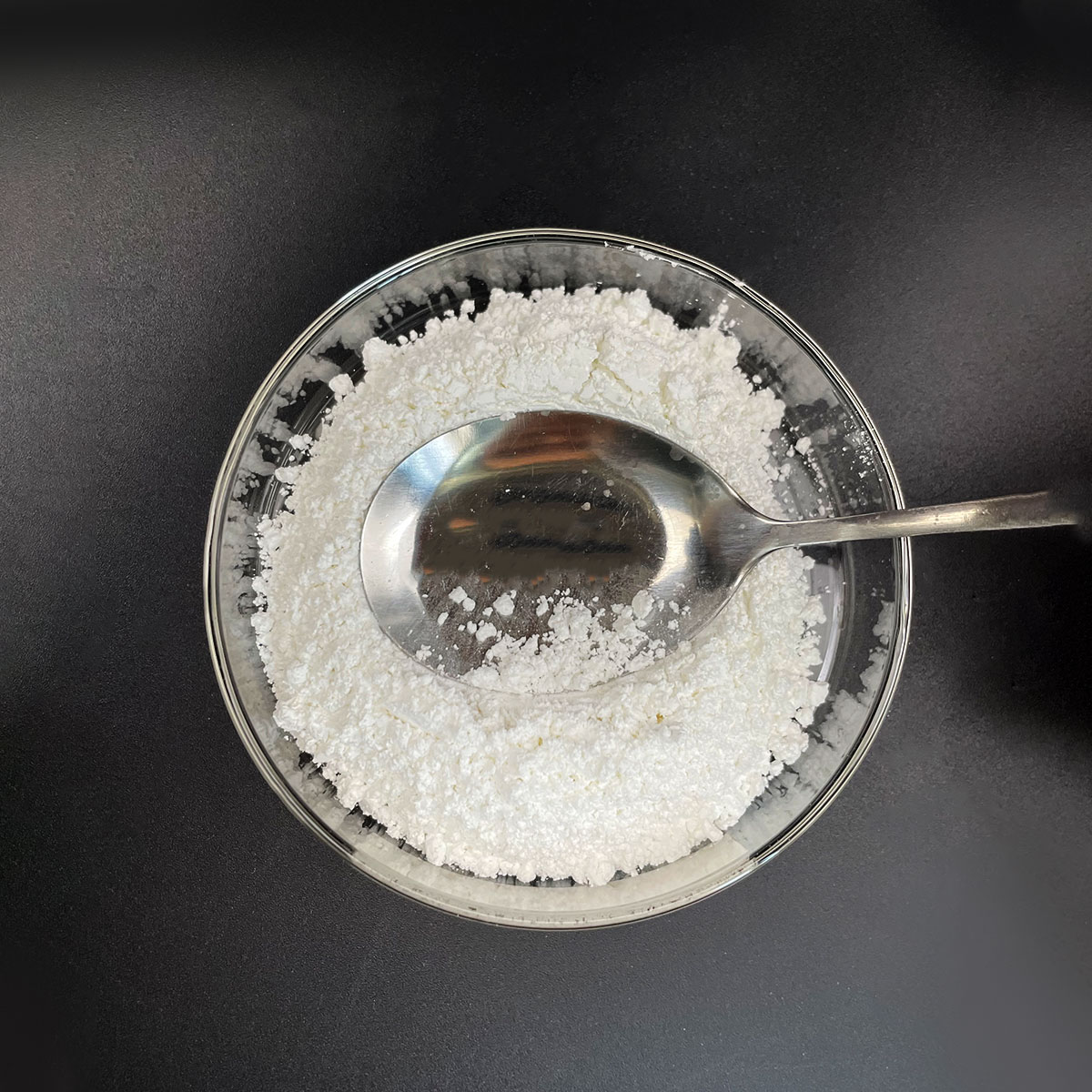

Specification of Asphalt Emulsifier for Anionic Bitumen Emulsion RS-1

The Asphalt Emulsifier for Anionic Bitumen Emulsion RS-1 is a specialized chemical representative designed to stabilize asphalt beads in water. It develops steady solutions for road building and construction and maintenance. The item works with anionic bitumen, ensuring compatibility with acidic accumulations. Its formulation permits regular performance across varying temperature levels and mixing problems.

Key requirements consist of a pH range of 1.5 to 3.5, crucial for maintaining emulsion stability. The emulsifier contains energetic ingredients at 40-50% concentration, making sure reliable bitumen diffusion. It operates within a viscosity variety of 20-50 centipoise, ideal for conventional spraying equipment. Storage space temperature levels must stay in between 5 ° C and 35 ° C to stop splitting up or deterioration. Life span is 6 months when kept in sealed containers away from direct sunlight.

The emulsifier produces RS-1 grade emulsions with a deposit material of 60-65% after breaking. Damaging time changes based on application requirements, commonly 15-30 mins under normal problems. The emulsion’s particle cost is highly adverse, ensuring bond to favorably charged surface areas like limestone or granite. It sustains mixing with aggregates including high fines or moisture, lowering pretreatment requirements.

Application approaches include spray-on techniques for surface treatments or blending with aggregates for cold paving. The emulsifier makes sure consistent finishing of bitumen on aggregate surfaces, improving binding. It performs well in ambient temperature levels as low as 5 ° C, extending the building period. Mixing proportions range 0.5% to 2.5% by weight of asphalt, depending upon job demands.

Safety and security protocols call for gloves and eye protection throughout handling. The emulsifier is non-flammable but might irritate skin on extended contact. Spills ought to be included with absorptive materials and disposed of according to regional guidelines.

The item adheres to ASTM D2397 standards for anionic solutions. Examining data confirms resistance to stripping and rutting in finished sidewalks. Compatibility contact local asphalt sources are recommended prior to massive usage. Set uniformity is verified through laboratory tests for thickness, pH, and deposit material.

(Asphalt Emulsifier for Anionic Bitumen Emulsion RS-1)

Applications of Asphalt Emulsifier for Anionic Bitumen Emulsion RS-1

Anionic Bitumen Emulsion RS-1 with asphalt emulsifier is widely used in road construction and maintenance. The product binds aggregates effectively. It creates durable surfaces for roads, parking lots, and driveways. The emulsion works well in cold weather. This reduces the need for heating materials. It saves energy and costs. Contractors prefer it for quick repairs. The emulsion cures fast. Traffic can resume sooner.

The emulsion is ideal for chip sealing. It coats stones evenly. This prevents loose debris. It extends pavement life. The mixture resists water damage. It protects roads from cracks and potholes. Maintenance becomes simpler. The emulsion is also used in slurry seals. These fill small cracks. They restore smooth surfaces. The process is cost-efficient. It avoids major reconstruction.

Soil stabilization is another key use. The emulsion mixes with loose soil. It forms a solid base. This strengthens weak ground. Builders use it for foundations. It supports structures safely. The emulsion is eco-friendly. It contains fewer chemicals. It reduces pollution risks. Workers handle it safely. Skin irritation is rare.

Cold mix asphalt production relies on this emulsion. Traditional hot mixes require high temperatures. The emulsion works without heat. This cuts fuel use. It lowers carbon emissions. Remote sites benefit. Transporting hot materials is harder. Cold mixes are easier to apply. They perform well in remote areas.

The emulsion serves as a tack coat. It bonds old and new pavement layers. The bond stays strong under heavy loads. It prevents layer separation. This ensures long-lasting roads. The product adapts to various climates. It performs in high heat or heavy rain.

Road crews use the emulsion for dust control. It binds loose particles on unpaved roads. Dust levels drop. Air quality improves. Drivers see better. Communities face fewer health issues. The treatment lasts months. Reapplication is simple.

Anionic Bitumen Emulsion RS-1 supports waterproofing. It seals roofs and basements. Water damage decreases. Structures stay dry. The emulsion is versatile. It meets diverse construction needs. Its flexibility makes it a top choice for professionals.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Asphalt Emulsifier for Anionic Bitumen Emulsion RS-1

Anionic Bitumen Emulsion RS-1 is a type of asphalt emulsifier. It helps mix bitumen with water for road construction. This product works in cold conditions. It reduces energy use.

What is Anionic Bitumen Emulsion RS-1 used for?

RS-1 binds bitumen to surfaces like aggregates. It creates stable mixtures for roads. It works best with acidic or neutral aggregates. Use it for chip seals, slurry seals, and cold mixes.

How does RS-1 work?

RS-1 breaks down bitumen into tiny droplets. These droplets mix evenly in water. The emulsion stays stable until applied. When the water evaporates, the bitumen sticks to surfaces. This creates a strong bond.

What temperatures are needed for RS-1?

Apply RS-1 between 50°F and 85°F. Cold weather slows drying. Hot weather speeds it up. Adjust application speed based on temperature. Store RS-1 in a cool, dry place. Avoid freezing or extreme heat.

Can RS-1 mix with other emulsifiers?

Do not mix RS-1 with cationic emulsifiers. They react badly. Use only anionic or non-ionic additives. Test compatibility before large-scale use. Follow supplier guidelines for safe blending.

How long does RS-1 stay usable?

RS-1 lasts 3-6 months in sealed containers. Check for separation or lumps before use. Stir well if layers form. Discard if the emulsion smells odd or thickens too much.

Is RS-1 safe to handle?

Wear gloves and goggles. Avoid skin contact. Work in ventilated areas. Rinse spills with water. Follow local disposal rules. Keep away from children and animals.

(Asphalt Emulsifier for Anionic Bitumen Emulsion RS-1)