Overview of Rdp Redispersible Emulsion Powder Redispersible Polymer Powder Rdp/Vae

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Rdp Redispersible Emulsion Powder Redispersible Polymer Powder Rdp/Vae

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Rdp Redispersible Emulsion Powder Redispersible Polymer Powder Rdp/Vae)

Specification of Rdp Redispersible Emulsion Powder Redispersible Polymer Powder Rdp/Vae

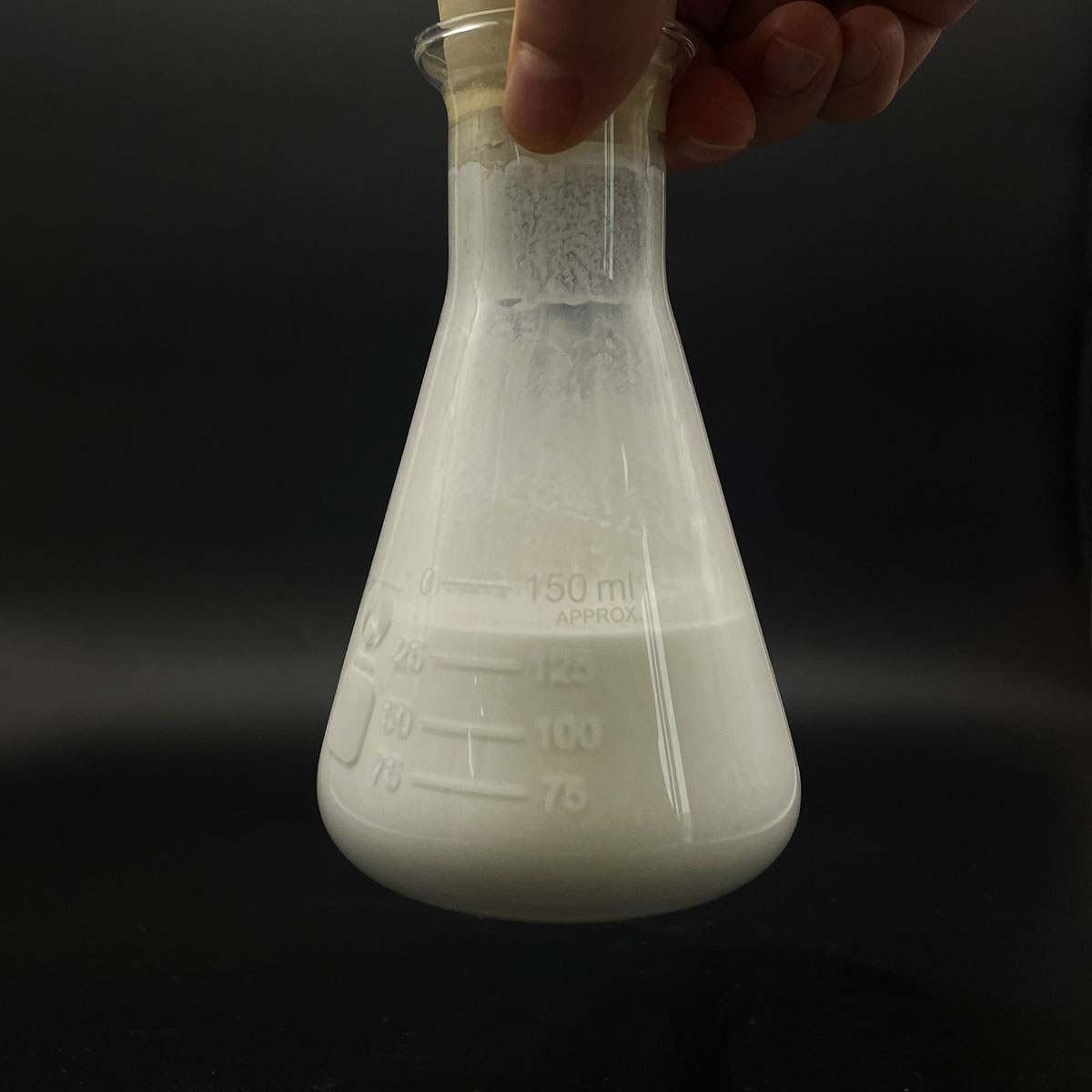

RDP Redispersible Emulsion Powder is a polymer powder made from plastic acetate-ethylene copolymer. This powder is widely used in building products. It boosts efficiency in products like floor tile adhesives, exterior insulation systems, and self-leveling compounds. The powder appears as a free-flowing white material. Fragment size ranges in between 80 and 150 microns. The pH degree is neutral, typically 6.0 to 8.0. This ensures compatibility with cement and various other alkaline building products. Ash material is around 10% to 15%, revealing excellent polymer purity. The powder dissolves quickly in water, creating a stable emulsion. This recovers the initial residential properties of the polymer binder.

RDP enhances attachment, versatility, and water resistance in dry-mix formulations. It minimizes splitting in cement-based mortars. Workability of the mixture boosts, permitting much easier application. The powder boosts cohesion, protecting against drooping on upright surfaces. It is compatible with additives like cellulose ethers and starch ethers. Storage needs a dry, trendy setting. Dampness exposure need to be stayed clear of to avoid clumping. The life span is six months under correct problems.

In floor tile adhesives, RDP increases bond toughness and open time. For outside insulation systems, it improves effect resistance and resilience. Self-leveling compounds get smoother surface areas and faster drying times. The powder forms an adaptable movie after water dissipation. This film binds bits securely, boosting mechanical residential or commercial properties. It lowers shrinking throughout treating, decreasing splits. RDP is included during dry-mix manufacturing. Dose varies between 1% and 5% by weight, depending on application needs.

The item satisfies global safety requirements. It is safe and environmentally friendly. No damaging materials are launched during use. RDP sustains sustainable building methods by boosting material performance. Home builders and makers favor it for constant top quality and dependability. It is suitable for both exterior and interior applications. Efficiency continues to be steady under differing temperature levels. This makes it excellent for diverse climates. Proper mixing guarantees uniform distribution in the final product. Checking validates conformity with sector demands for strength and longevity.

(Rdp Redispersible Emulsion Powder Redispersible Polymer Powder Rdp/Vae)

Applications of Rdp Redispersible Emulsion Powder Redispersible Polymer Powder Rdp/Vae

Rdp redispersible solution powder is a polymer powder made from vinyl acetate-ethylene copolymer. It is commonly utilized in building products. The powder mixes conveniently with water. It forms a versatile movie after drying. This enhances the efficiency of cement-based products. Contractors utilize it in tile adhesives. Rdp makes the adhesive sticky. It protects against tiles from sliding. The glue becomes more durable. It resists water and fractures. Rdp is added to self-leveling floor substances. It aids the substance flow smoothly. The surface area remains level without reducing. This accelerates floor covering work. Exterior insulation systems use Rdp. It binds insulation boards to walls. The layer remains strong in altering weather. It stops fractures from forming. Rdp enhances concrete makes and smudges. It makes them stick much better to surface areas. The finish is smoother. It manages activity without damaging. Rdp is made use of in repair mortars. The mortar sticks well to old concrete. It repairs splits and spalls. The repair work lasts much longer. Plaster products like joint fillers utilize Rdp. It makes plaster less brittle. The filler withstands scrapes. It dries without reducing. Rdp operates in low-cost dry-mix formulas. Contractors save time on-site. The powder remains steady in storage. It does not clump or ruin. Rdp is secure for workers. It has no strong fumes. The powder reduces waste. Percentages offer big results. Rdp supports environmentally friendly construction. It reduces energy use in buildings. The material is recyclable. Rdp meets international high quality standards. It is tested for stamina and safety. Producers trust its consistency. Projects end up much faster with fewer issues. Rdp is a key component for modern building. It upgrades conventional materials. The outcomes are trusted and resilient.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Rdp Redispersible Emulsion Powder Redispersible Polymer Powder Rdp/Vae

RDP stands for Redispersible Polymer Powder. It’s a free-flowing white powder made by spray-drying emulsions. This powder is used in construction materials like mortars, adhesives, and coatings. Common polymers in RDP include vinyl acetate-ethylene (VAE), vinyl acetate versatate (VAC), and acrylics. When mixed with water, RDP forms a film that improves flexibility, adhesion, and water resistance in building materials.

How does RDP work? RDP particles redisperse in water during mixing. After drying, the polymer film binds cement, sand, and additives together. This film acts like a glue. It makes materials stick better to surfaces. It also helps them resist cracks, water, and wear.

Where is RDP used? It’s added to tile adhesives for better grip. It’s in exterior insulation systems to prevent cracks. Self-leveling floor compounds use RDP for smooth finishes. Repair mortars rely on it for durability. Cement-based renders with RDP last longer in harsh weather.

What are the benefits of RDP? It makes mortars easier to apply. It strengthens adhesion between materials and surfaces. It reduces cracking by improving flexibility. It helps materials hold water longer, which is good for curing. It works well with cement, lime, and other additives.

How should RDP be stored and used? Keep it in a dry, cool place. Avoid moisture to prevent clumping. Store bags sealed tightly. Mix RDP with dry ingredients first. Add water gradually to activate the powder. Follow the manufacturer’s instructions for mixing ratios. Testing small batches ensures the right performance.

(Rdp Redispersible Emulsion Powder Redispersible Polymer Powder Rdp/Vae)