Overview of Silicone Sealant Silicone Sealant Raw Material 80000 Cst Oh Polymer

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Silicone Sealant Silicone Sealant Raw Material 80000 Cst Oh Polymer

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Silicone Sealant Silicone Sealant Raw Material 80000 Cst Oh Polymer)

Specification of Silicone Sealant Silicone Sealant Raw Material 80000 Cst Oh Polymer

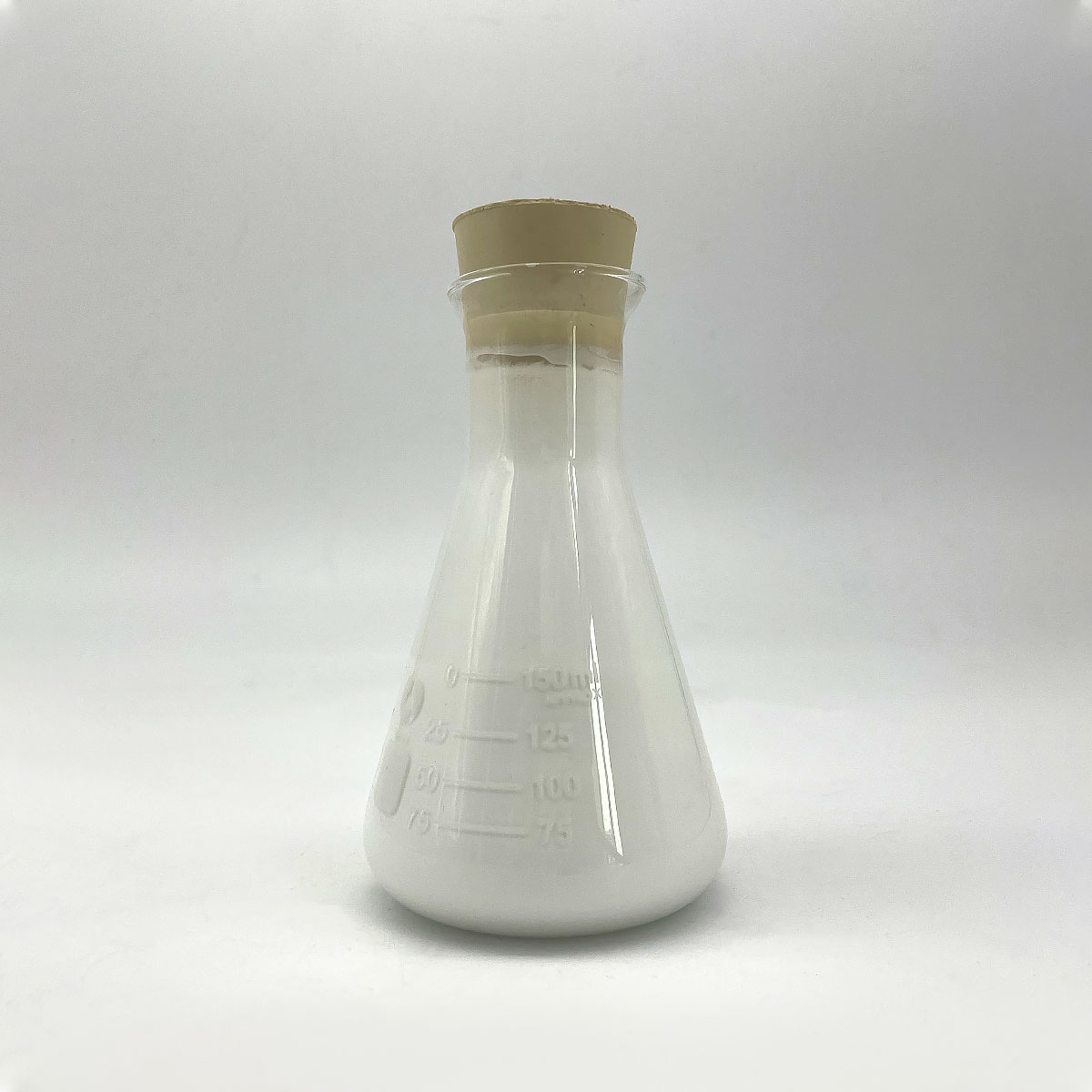

Silicone Sealer Raw Material 80000 Cst OH Polymer acts as a high-quality base for creating long lasting silicone sealants. This product includes a viscosity of 80000 centistokes (Cst), making it thick yet simple to manage throughout production. The hydroxyl (OH) polymer structure makes certain solid adhesion to different surface areas like glass, steel, and plastic. It stands up to severe temperatures, keeping versatility from -50 ° C to

200 ° C. This polymer is made for creating sealers made use of in building, automotive, and electronics. It develops leak-proof and impermeable bonds, preventing leaks in joints or voids. The product treatments at area temperature level when revealed to dampness, creating a durable rubber-like surface. It stays steady under UV light and extreme climate, lowering wear gradually.

The 80000 Cst thickness enables smooth application without leaking or sagging. It mixes well with ingredients like pigments or fillers to satisfy details product demands. The OH group in the polymer boosts bonding stamina, ensuring the sealer sticks firmly even on hard-to-adhere surfaces.

Security is a concern. The raw product is non-toxic and free from dangerous solvents. It satisfies worldwide safety standards for commercial and customer usage. Proper air flow is still advised during managing to avoid inhaling fumes.

Treating time depends upon humidity and temperature. Higher humidity quicken curing. A slim layer typically dries within 30 minutes, getting to complete toughness in 24 hours. The cured sealant remains versatile, absorbing activity or vibrations without fracturing.

Storage problems matter. Maintain the material in an awesome, completely dry area away from straight sunlight. Use secured containers to prevent dampness absorption prior to production. Service life depends on year when saved properly.

This silicone polymer sustains customized solutions. Producers adjust hardness, flexibility, or color by changing additives. It operates in automated giving systems or hands-on applications, fitting different production scales. Compatibility screening is advised for brand-new mixes to make sure efficiency.

(Silicone Sealant Silicone Sealant Raw Material 80000 Cst Oh Polymer)

Applications of Silicone Sealant Silicone Sealant Raw Material 80000 Cst Oh Polymer

Silicone sealant is a functional adhesive used in many markets. It bonds materials efficiently and resists water, heat, and climate. The raw product 80000 Cst OH Polymer plays a vital duty in its performance. This polymer provides the sealer flexibility and toughness.

Silicone sealant works in building for securing home windows, doors, and joints. It protects against air and water leakages in structures. It sticks well to glass, metal, and concrete. In the auto sector, it seals components like windshields and engines. It takes care of vibrations and temperature level changes.

The 80000 Cst OH Polymer is a high-viscosity silicone liquid. It forms the base of the sealant. The polymer’s long-chain structure enhances flexibility. This assists the sealer stay undamaged under tension. It also improves attachment to surfaces. The polymer resists UV light and chemicals. This makes the sealant last longer outdoors.

In electronic devices, silicone sealant protects circuits and components. It shields against dampness and dirt. The 80000 Cst OH Polymer ensures the sealer remains steady in severe conditions. It does not damage down in high humidity or warm.

House repair services use silicone sealer for bathrooms and kitchens. It secures sinks, ceramic tiles, and pipelines. The polymer’s resistance to mold and mildew maintains areas hygienic. It stays flexible even after drying. This prevents cracks over time.

Suppliers pick the 80000 Cst OH Polymer for high quality. It meets safety and security criteria for different applications. The polymer blends quickly with ingredients like fillers and curing agents. This allows personalization for specific needs.

Silicone sealant made with this polymer works in medical devices and industrial equipment. It meets stringent requirements for non-toxicity and dependability. The polymer’s uniformity makes sure smooth application. It remedies quickly without diminishing.

The raw material’s high viscosity enhances gap-filling. It fills uneven surfaces better than thinner options. This decreases waste and enhances effectiveness. Individuals obtain a strong, long-lasting seal whenever.

Silicone sealant’s adaptability originates from the 80000 Cst OH Polymer. Its homes make the sticky appropriate for demanding environments. Industries rely on it for regular efficiency.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Silicone Sealant Silicone Sealant Raw Material 80000 Cst Oh Polymer

What is Silicone Sealant Raw Material 80000 Cst OH Polymer?

This material is a key component in making silicone sealants. It has high viscosity (80,000 centistokes) and contains hydroxyl (OH) groups. These features help create strong, flexible bonds. The polymer works well in adhesives, coatings, and waterproofing products.

Where is this silicone polymer used?

It is common in construction, automotive, and electronics. Builders use it for sealing windows, joints, or roofs. Car makers apply it to gaskets or engine parts. Electronics manufacturers rely on it to protect circuits from moisture. The material resists heat, water, and chemicals.

Why does viscosity matter?

High viscosity means the polymer is thick. This thickness helps it stay in place during application. It prevents dripping or sagging on vertical surfaces. The 80,000 Cst grade balances ease of use with performance. Lower viscosity might spread too thin. Higher viscosity could be hard to handle.

Is this material safe?

The raw polymer is stable under normal conditions. It is non-toxic after curing. Follow safety guidelines when handling uncured material. Wear gloves and avoid skin contact. Use in well-ventilated areas. Keep away from open flames.

How long does it last?

Stored properly, the polymer stays usable for about 12 months. Keep it sealed in a cool, dry place. Avoid direct sunlight or extreme temperatures. Check expiration dates before use. Old material might thicken or cure poorly.

(Silicone Sealant Silicone Sealant Raw Material 80000 Cst Oh Polymer)