Overview of Alumina Microsphere Used in Fluidized Bed as Catalyst Carrier

Amphoteric surfactants are a unique class of surface-active agents that possess both cationic and anionic properties, depending on the pH of the system they are in. They contain both a positively charged group (like a quaternary ammonium salt) and a negatively charged group (such as a carboxylate or sulfonate), which can ionize depending on the surrounding conditions. This dual nature grants them exceptional versatility, making them effective in a wide range of pH environments and compatible with other surfactant types. They are known for their mildness and excellent dermatological compatibility, rendering them particularly suitable for personal care applications.

Features of Alumina Microsphere Used in Fluidized Bed as Catalyst Carrier

-

pH Responsiveness: Their charge varies with pH, becoming cationic in acidic conditions and anionic in alkaline, with a zwitterionic (neutral) state at the isoelectric point.

-

Mildness: Known for being gentle on skin and eyes, making them ideal for sensitive applications like baby care and personal hygiene products.

-

Foaming Properties: Can generate rich, stable foam even in hard water conditions, enhancing their use in cleaning products.

-

Emulsification: Efficient emulsifiers capable of forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions, depending on the formulation and pH.

-

Compatibility: Because they have both anionic and cationic properties, they are compatible with other types of surfactants and can work synergistically to enhance cleaning effects.

-

Biodegradability: Many amphoteric surfactants are readily biodegradable, contributing to their environmentally friendly profile.

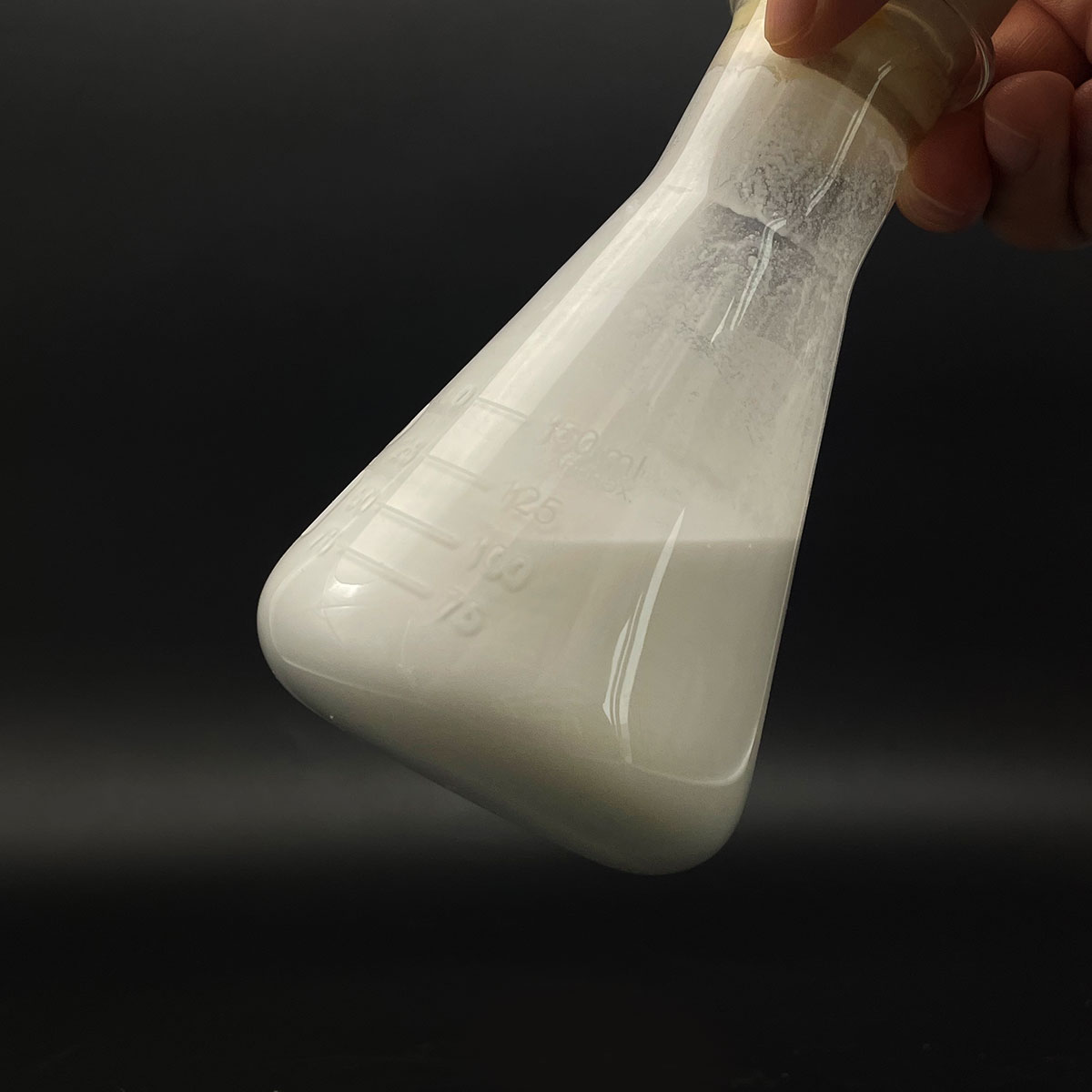

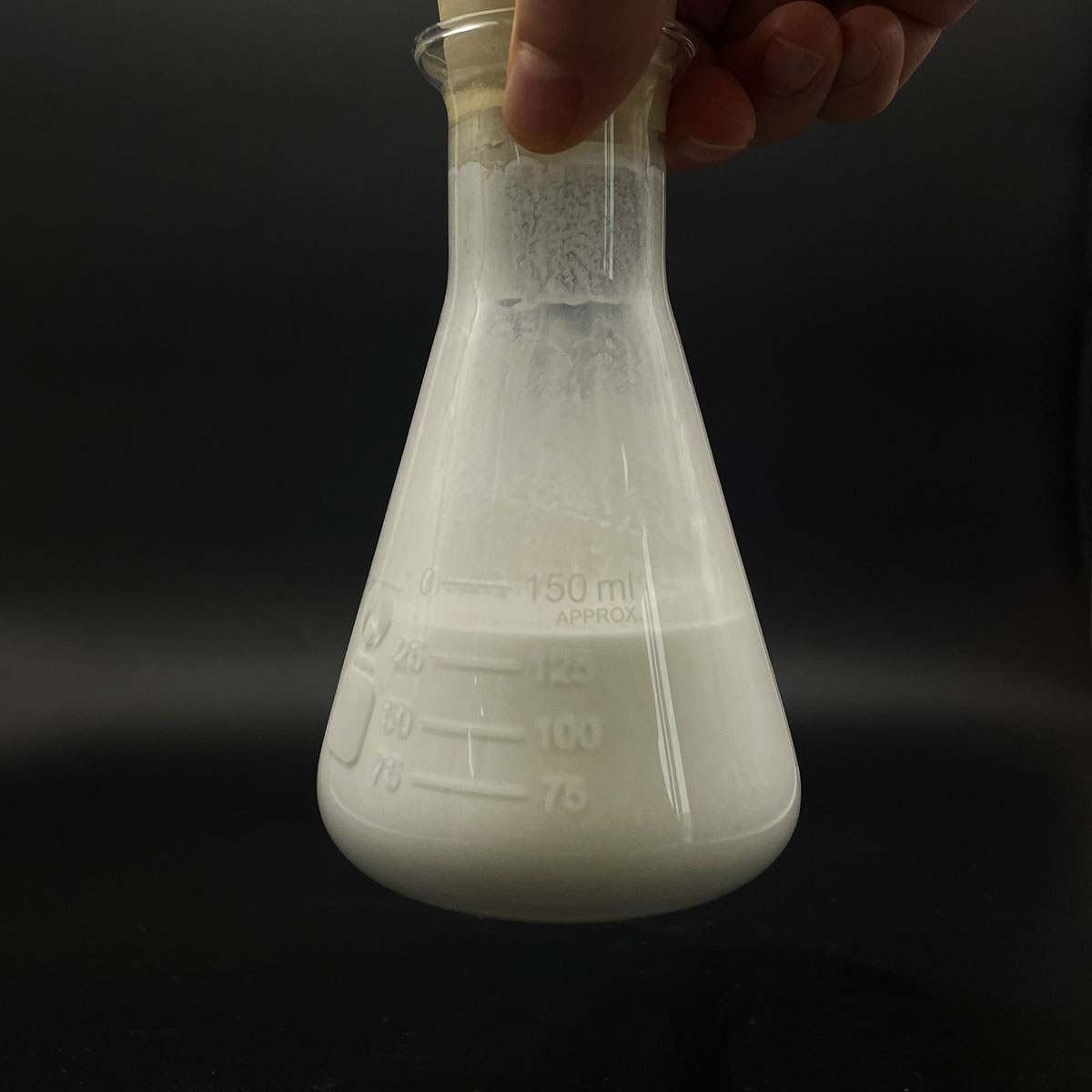

(Alumina Microsphere Used in Fluidized Bed as Catalyst Carrier)

Specification of Alumina Microsphere Used in Fluidized Bed as Catalyst Carrier

Alumina microspheres work as stimulant providers in fluidized bed systems. These balls are made from high-purity light weight aluminum oxide. They have a spherical form for also call with catalysts. The particle dimension ranges in between 50 and 150 micrometers. This dimension ensures smooth fluidization in the bed. The area of the microspheres is in between 200 and 350 m TWO/ g. A large surface sustains energetic stimulant elements. This improves reaction performance. The pore framework is flexible. The majority of pores are mesoporous. This structure enables very easy movement of reactants and products. It prevents clogs throughout reactions.

The microspheres show high warmth resistance. They handle temperatures approximately 1000 ° C without breaking down. This security suits high-temperature procedures. They withstand chemical rust. Acids and bases do not harm them conveniently. This prolongs their life span. The mechanical toughness is solid. They withstand rubbing and stress in fluidized beds. This minimizes wear and dust development.

Alumina microspheres work well with metals like nickel or cobalt. These metals function as stimulants. The spheres spread out the metals uniformly. This maintains the catalyst energetic for longer. Catalyst flow through the bed smoothly. Warmth spreads equally during responses. This stays clear of hotspots. The outcome corresponds product quality.

Fluidized beds require materials that mix well with gases. These microspheres fulfill that demand. Their uniform dimension prevents uneven fluidization. They remain stable under quick gas flow. This lowers energy use. Industrial refines take advantage of reliable performance. Applications include petroleum refining and chemical production.

The microspheres are recyclable. After responses, they separate easily from by-products. Regrowth approaches like calcination restore their structure. This cuts expenses with time. Their adaptability fits various response problems. Custom-made dimensions and pore structures are readily available. This satisfies certain procedure requirements.

Alumina microspheres enhance catalyst effectiveness. They stabilize surface, strength, and thermal residential properties. These functions make them suitable for demanding industrial environments.

(Alumina Microsphere Used in Fluidized Bed as Catalyst Carrier)

Applications of Alumina Microsphere Used in Fluidized Bed as Catalyst Carrier

Alumina microspheres act as catalyst service providers in fluidized bed systems. These tiny, spherical bits supply a stable structure for catalysts. Their high surface area permits active parts to spread uniformly. This improves reaction efficiency. Fluidized beds rely on smooth movement of fragments. Alumina microspheres meet this requirement with their uniform size and shape. They resist wear under intense problems. This makes them trustworthy for lasting use.

Refineries make use of alumina microspheres in processes like catalytic fracturing. Right here, hefty hydrocarbons break into lighter gas. The microspheres hold catalysts that quicken reactions. Their thermal security avoids breakdown at high temperatures. This makes certain regular efficiency. Petrochemical plants use them in creating plastics and synthetic fibers. The spheres deal with acidic or alkaline settings without deteriorating. This flexibility supports varied chain reaction.

Environmental applications include lowering dangerous discharges. Alumina microspheres bring catalysts in systems that clean commercial exhaust. They assist transform pollutants like nitrogen oxides into harmless compounds. Their porous structure traps response byproducts. This keeps stimulants active longer. Nuclear power plant and manufacturing facilities take advantage of this innovation. It helps satisfy stringent discharge standards.

The oil and gas market makes use of these microspheres in gas-to-liquid procedures. They sustain catalysts that transform gas into fluid fuels. The spheres hold up against high stress and temperature level changes. This lowers downtime for maintenance. Their reduced thickness allows smooth fluidization. This cuts power prices throughout operation.

Drug and specialty chemical industries utilize alumina microspheres for exact responses. They enable regulated launch of stimulants in multi-step processes. Their inert nature prevents unwanted side responses. This improves product purity. Personalized pore dimensions allow customers customize them for particular demands.

Alumina microspheres supply mechanical strength and chemical resistance. These traits make them excellent for demanding industrial settings. Their duty in fluidized beds covers energy, atmosphere, and manufacturing. By enhancing driver efficiency, they drive effectiveness and sustainability throughout markets.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Alumina Microsphere Used in Fluidized Bed as Catalyst Carrier

Alumina microspheres are widely used as catalyst carriers in fluidized beds. Here are five common questions about them. What are alumina microspheres? They are small, spherical particles made from aluminum oxide. Their uniform shape and size make them ideal for fluidized bed applications. They provide a stable surface for catalysts to attach to. This improves reaction efficiency.

Why use alumina microspheres in fluidized beds? Fluidized beds need materials that can handle constant movement. Alumina microspheres are hard and wear-resistant. They stay intact under high-pressure conditions. Their spherical shape allows even fluid flow. This prevents blockages and keeps the bed stable.

What advantages do alumina microspheres offer over other carriers? They have a high surface area. This gives catalysts more space to work. They resist heat well. This is important in high-temperature reactions. They also last longer than many alternatives. This reduces replacement costs and downtime.

How do you pick the right alumina microspheres for a fluidized bed? Focus on particle size and density. Smaller particles improve contact between the catalyst and reactants. Density affects how they move in the bed. Match these properties to your system’s requirements. Check chemical compatibility too. The material must not react with your catalyst or process chemicals.

Do alumina microspheres need special handling or storage? Keep them dry. Moisture can cause clumping or damage their structure. Store them in sealed containers. Avoid rough handling to prevent dust formation. Dust can affect performance. Clean the bed regularly to remove debris. This maintains efficiency over time.

(Alumina Microsphere Used in Fluidized Bed as Catalyst Carrier)