Overview of Alumina Microspheres / Alumina Ball for New Catalyst Carriers

Amphoteric surfactants are a unique class of surface-active agents that possess both cationic and anionic properties, depending on the pH of the system they are in. They contain both a positively charged group (like a quaternary ammonium salt) and a negatively charged group (such as a carboxylate or sulfonate), which can ionize depending on the surrounding conditions. This dual nature grants them exceptional versatility, making them effective in a wide range of pH environments and compatible with other surfactant types. They are known for their mildness and excellent dermatological compatibility, rendering them particularly suitable for personal care applications.

Features of Alumina Microspheres / Alumina Ball for New Catalyst Carriers

-

pH Responsiveness: Their charge varies with pH, becoming cationic in acidic conditions and anionic in alkaline, with a zwitterionic (neutral) state at the isoelectric point.

-

Mildness: Known for being gentle on skin and eyes, making them ideal for sensitive applications like baby care and personal hygiene products.

-

Foaming Properties: Can generate rich, stable foam even in hard water conditions, enhancing their use in cleaning products.

-

Emulsification: Efficient emulsifiers capable of forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions, depending on the formulation and pH.

-

Compatibility: Because they have both anionic and cationic properties, they are compatible with other types of surfactants and can work synergistically to enhance cleaning effects.

-

Biodegradability: Many amphoteric surfactants are readily biodegradable, contributing to their environmentally friendly profile.

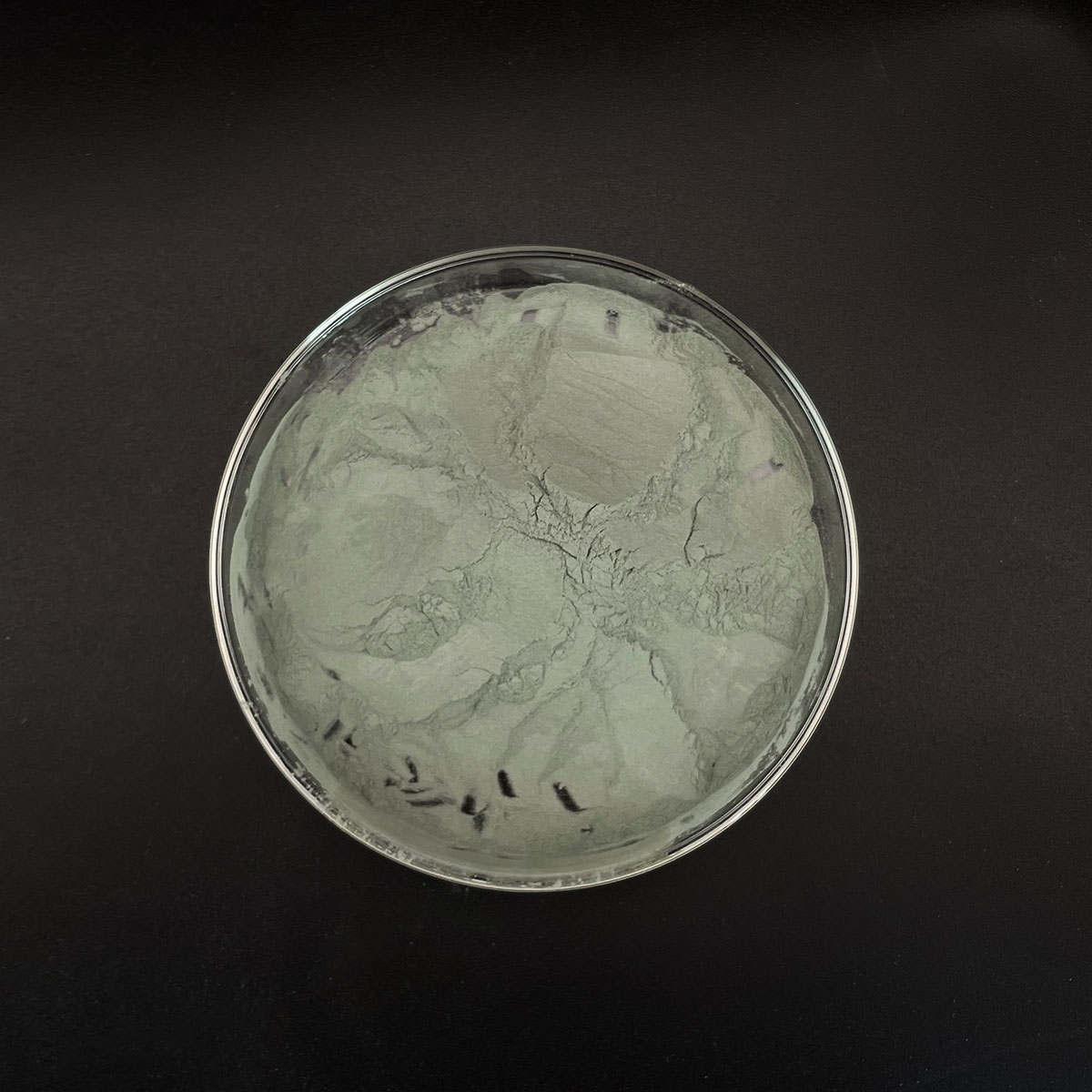

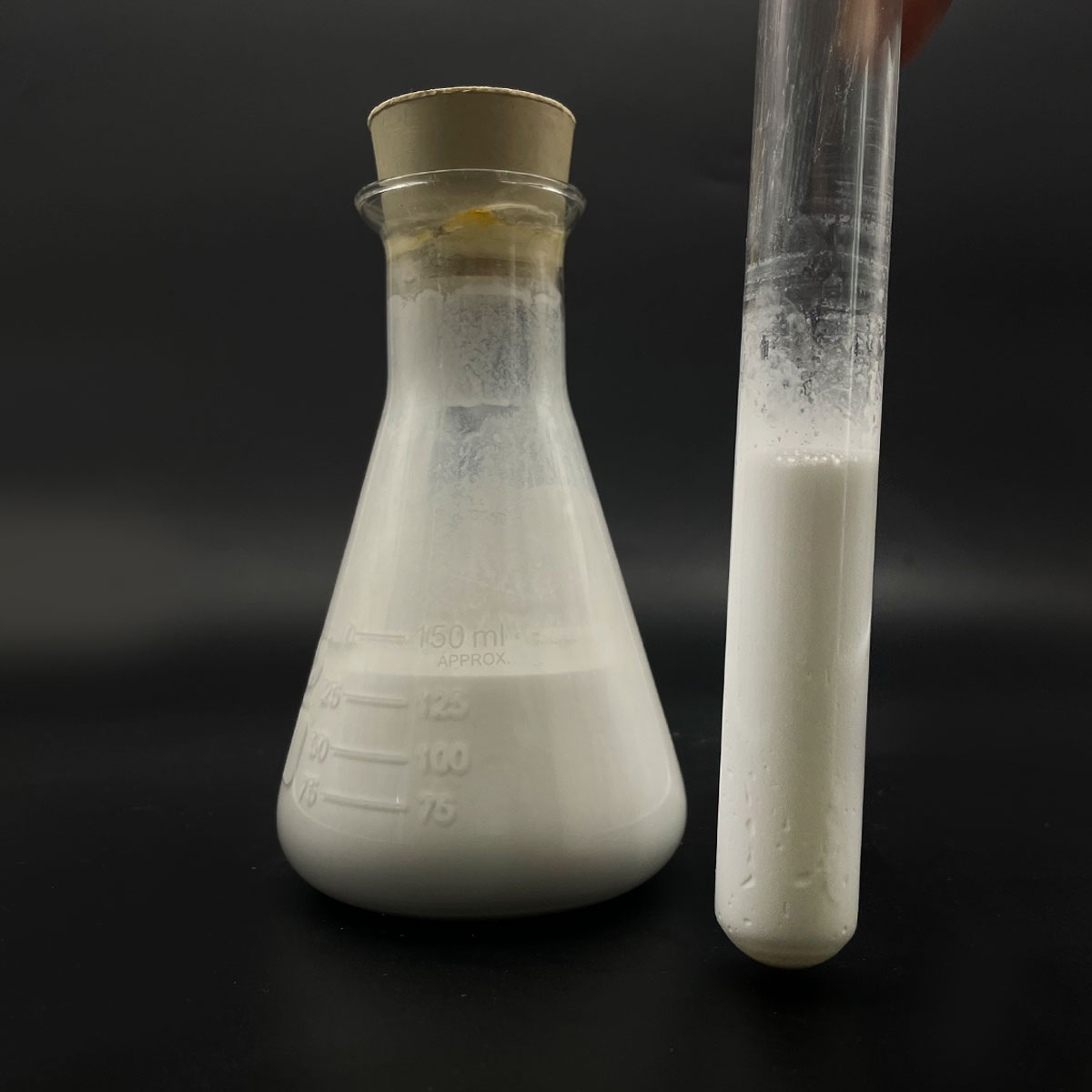

(Alumina Microspheres / Alumina Ball for New Catalyst Carriers)

Specification of Alumina Microspheres / Alumina Ball for New Catalyst Carriers

Alumina microspheres, also known as alumina spheres, act as innovative driver providers designed for high-performance commercial applications. These spherical fragments are made from high-purity light weight aluminum oxide, guaranteeing chemical security and sturdiness under severe problems. The main requirements include a pureness degree of 99.5% or greater, an area varying in between 150-300 m TWO/ g, and a regulated pore structure enhanced for catalytic responses. The consistent particle size, commonly in between 1-5 mm in diameter, allows also circulation of active catalytic products, maximizing response efficiency.

The microspheres feature exceptional thermal resistance, maintaining architectural honesty at temperatures up to 1600 ° C. This makes them suitable for processes entailing rapid home heating or cooling cycles. Their high mechanical toughness reduces damage during taking care of or operation, minimizing downtime and upkeep prices. The smooth surface of the alumina rounds decreases rubbing between particles, protecting against abrasion and prolonging the catalyst’s life-span.

A crucial benefit hinges on their chemical inertness. Alumina microspheres stand up to corrosion from acids, alkalis, and natural solvents, even in high-temperature environments. This ensures consistent performance in aggressive chain reaction. The customized pore dimension distribution enhances mass transfer prices, boosting reactant access to active sites. This enhances catalytic task and selectivity, essential for procedures like hydrogenation, oxidation, and desulfurization.

Applications span industries such as petrochemical refining, environmental management, and chemical synthesis. They are commonly used in catalytic converters, hydrogen manufacturing systems, and VOC therapy systems. Their low attrition rate and high recyclability make them affordable for long-lasting operations. Adjustable parameters like bit density and porosity enable adjustment to certain procedure demands.

Alumina microspheres undergo rigorous quality assurance, consisting of X-ray diffraction for phase pureness and wager evaluation for surface confirmation. Each set is evaluated for crush strength and thermal shock resistance. This assures dependability in demanding commercial setups.

(Alumina Microspheres / Alumina Ball for New Catalyst Carriers)

Applications of Alumina Microspheres / Alumina Ball for New Catalyst Carriers

Alumina microspheres (alumina spheres) serve as innovative driver providers in different industries. Their one-of-a-kind framework and buildings make them suitable for demanding chemical processes. The high surface enables energetic catalytic materials to spread equally. This enhances reaction performance and minimizes waste. Alumina balls endure severe temperature levels without breaking down. This thermal stability makes certain durable performance in high-heat environments.

In the petrochemical market, alumina microspheres are extensively used for refining petroleum. They help damage huge hydrocarbon particles into smaller sized ones throughout cracking. This improves gas quality and manufacturing speed. Alumina spheres additionally operate in changing reactions to update low-value gas into high-octane gas. Their resistance to sulfur and other corrosive aspects avoids damage in time.

The auto market counts on alumina-based stimulants to reduce unsafe discharges. Alumina spheres sustain catalytic converters by enabling responses that turn poisonous gases into more secure substances like water and carbon dioxide. Their longevity guarantees regular performance under rough engine problems. This helps vehicles satisfy stringent environmental regulations.

Chemical manufacturing utilizes alumina microspheres in producing plastics, fertilizers, and drugs. Their porous structure supplies adequate area for reactions between gases and liquids. Alumina rounds speed up procedures like oxidation and hydrogenation. This reduces energy usage and lowers expenses.

Environmental applications consist of air and water purification systems. Alumina balls catch toxins or assistance stimulants that damage down contaminants. They remove hefty steels from wastewater or transform unstable organic substances into safe byproducts.

Alumina microspheres are personalized in dimension, porosity, and composition. This adaptability permits industries to customize them for details responses or tools. Their low wear rate minimizes downtime for substitutes. This integrity makes them an affordable selection for large operations.

Study continues to expand their usage in arising areas like renewable energy. Alumina balls reveal promise in hydrogen manufacturing and carbon capture modern technologies. Their flexibility guarantees they stay pertinent as commercial needs evolve.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Alumina Microspheres / Alumina Ball for New Catalyst Carriers

Alumina microspheres, also called alumina balls, serve as catalyst carriers in chemical processes. Here are 5 FAQs about them.

What are alumina microspheres? They are small, spherical particles made from high-purity aluminum oxide. Their uniform size and shape help distribute catalysts evenly. This improves reaction efficiency in industrial applications like petroleum refining or gas purification.

Why use alumina balls as catalyst carriers? They have a high surface area. This allows more active catalyst material to attach. They resist heat well, maintaining stability in high-temperature reactions. Their hardness prevents breaking under pressure. These traits make them reliable for long-term use.

How do temperature changes affect alumina microspheres? They handle extreme heat, up to 1600°C, without degrading. Thermal shock resistance means they won’t crack if temperatures shift suddenly. This is important in processes like catalytic cracking, where temperatures fluctuate fast.

Are alumina microspheres chemically stable? Yes. They resist corrosion from acids, alkalis, and organic solvents. This stability keeps the catalyst active longer. It reduces downtime for replacing carriers. Their inert nature avoids unwanted side reactions, ensuring product purity.

How do alumina balls compare to other catalyst carriers? They outperform materials like silica or activated carbon. Silica can break down in acidic conditions. Activated carbon has lower heat resistance. Alumina’s combination of strength, thermal stability, and chemical inertness makes it a top choice for harsh industrial environments.

What should users check before buying alumina microspheres? Confirm the particle size matches the reactor’s requirements. Verify purity levels—higher purity means fewer impurities interfering with reactions. Check porosity if the catalyst needs surface penetration. Test mechanical strength data to ensure durability under operational stress.

Proper storage matters. Keep alumina balls dry to prevent moisture absorption. Handle them carefully to avoid chipping. Follow the manufacturer’s guidelines for loading them into reactors.

(Alumina Microspheres / Alumina Ball for New Catalyst Carriers)