Overview of Anionic Polyacrylamide Concrete Polymer Powder

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Anionic Polyacrylamide Concrete Polymer Powder

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

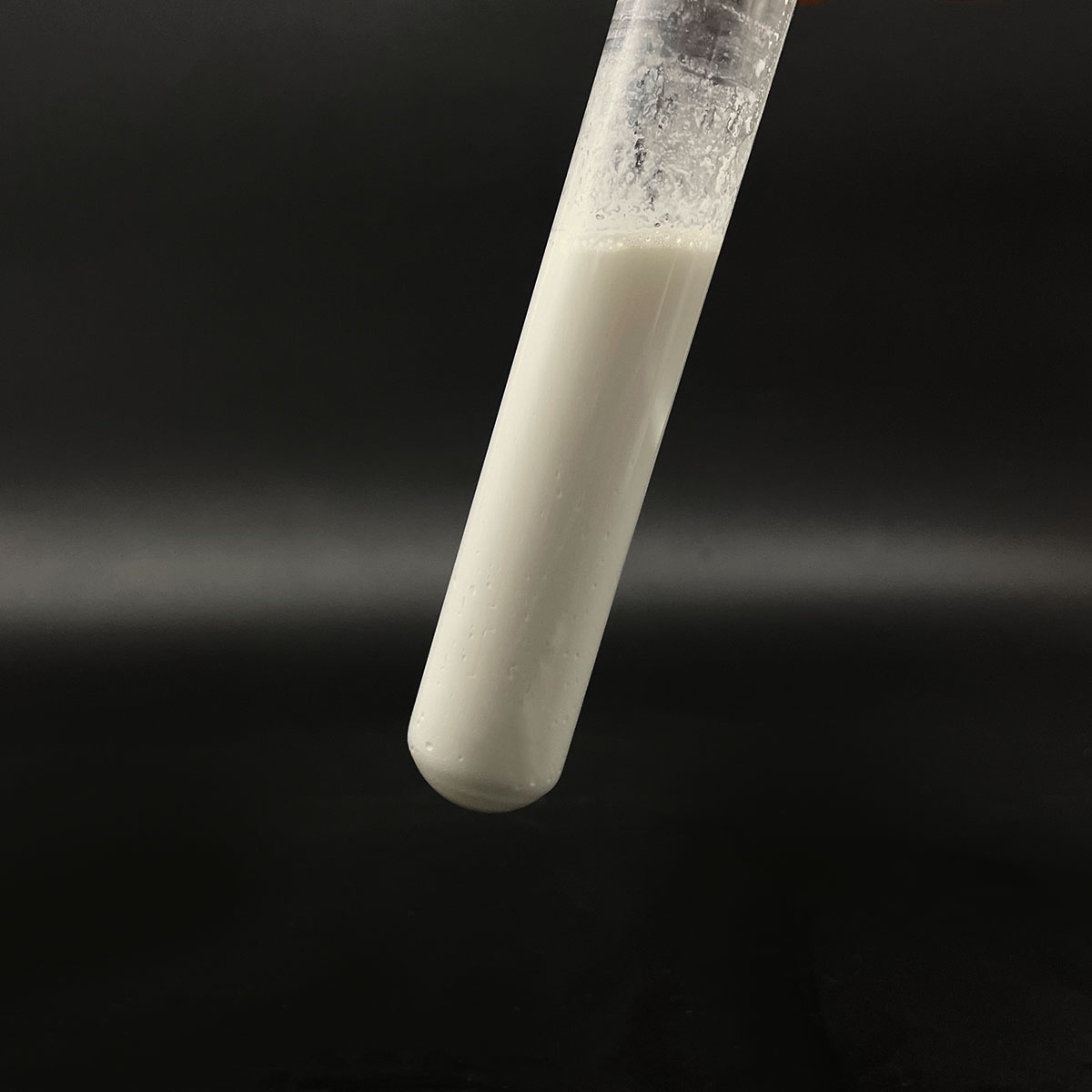

(Anionic Polyacrylamide Concrete Polymer Powder)

Specification of Anionic Polyacrylamide Concrete Polymer Powder

Anionic Polyacrylamide (APAM) Concrete Polymer Powder is a high-performance water-soluble polymer made to boost the buildings of concrete and cement-based materials. It serves as a rheology modifier, water reducer, and bonding representative, improving workability, durability, and strength. Below are the vital requirements of this product:

** Physical Features **: The powder is typically white or off-white in look, with a fine granular texture. It has a bulk density of approximately 0.6– 0.8 g/cm ³ and a moisture material of ≤ 5% to guarantee stability during storage space. The bit dimension varies in between 80– 100 mesh, making it possible for rapid dissolution in water.

** Chemical Composition **: The item is synthesized from acrylamide and anionic monomers (e.g., sodium acrylate) through copolymerization. It lugs a high unfavorable fee density (anionic) due to sulfonic or carboxyl groups, which promotes adsorption onto cement fragments. The molecular weight varieties in between 10– 20 million Daltons, adding to its viscosity-building and flocculation capacities.

** Practical Efficiency **: When contributed to concrete blends (0.1– 0.5% by concrete weight), APAM improves cohesion, lowers partition, and enhances pumpability. It reduces water need by 10– 25% while keeping depression, bring about greater compressive stamina (up to 20% enhancement). The polymer forms an adaptable film within the matrix, boosting split resistance, freeze-thaw toughness, and resistance to chemical erosion.

** Compatibility **: Compatible with Rose city cement, fly ash, slag, and most admixtures (e.g., superplasticizers). Nevertheless, compatibility testing is advised when integrating with cationic additives.

** Dose & Application **: Optimal dosage depends on concrete kind, accumulated gradation, and desired concrete efficiency. Pre-dissolve the powder in water (0.1– 0.5% solution) prior to contributing to the mix. Mixing time might need change to ensure consistent dispersion.

** Security & Storage **: Non-toxic yet might trigger eye or skin inflammation in powder form. Usage PPE during taking care of. Shop in a dry, aerated area away from moisture and direct sunshine. Service life is 12– 24 months in sealed product packaging.

** Conformity **: Fulfills ASTM C494 Type S (water-reducing admixture) and ISO 14001 ecological requirements. Reduced recurring acrylamide material (

(Anionic Polyacrylamide Concrete Polymer Powder)

Applications of Anionic Polyacrylamide Concrete Polymer Powder

Anionic Polyacrylamide (APAM) Concrete Polymer Powder is a functional, high-performance additive commonly utilized in building and construction and civil engineering to boost the residential or commercial properties of concrete and related products. Its special molecular framework, characterized by a high adverse fee density, makes it possible for efficient communication with concrete particles, accumulations, and water, resulting in boosted toughness, workability, and toughness in concrete applications.

** Secret Applications Include: **.

1. ** Concrete Additive **: APAM acts as a water-reducing representative and plasticizer, boosting the workability of fresh concrete without compromising toughness. It minimizes water web content in mixes, improving compressive strength and decreasing contraction cracks. This makes it suitable for high-strength concrete used in bridges, dams, and high-rise buildings.

2. ** Soil Stablizing **: In geotechnical engineering, APAM is blended with soil to enhance communication and decrease disintegration. It binds loosened fragments, producing a steady base for roads, embankments, and foundations, especially in sandy or silty dirts vulnerable to changing.

3. ** Dust Reductions **: APAM forms a safety movie when put on unpaved surface areas, effectively capturing dust bits. This is critical for building sites, mining locations, and short-term roadways, making certain compliance with environmental guidelines.

4. ** Mortar and Cement Improvement **: Contributed to cement mortars or tile adhesives, APAM improves bond, flexibility, and water retention. This leads to more powerful bonds for tiling, gluing, and repair work, also in high-moisture environments.

5. ** Wastewater Therapy in Building **: APAM flocculates put on hold solids in wastewater created throughout concrete manufacturing or washing equipment. This aids in reusing water, lowering prices, and reducing environmental impact.

6. ** Precast Concrete Production **: APAM accelerates establishing times and improves surface area finish in precast components like pipelines, panels, and obstructs, making sure harmony and lowering issues.

7. ** Shotcrete Applications **: In tunnel linings or slope stablizing, APAM enhances the communication of splashed concrete, decreasing rebound and material waste while improving adhesion to upright or above surface areas.

8. ** Attractive Concrete **: APAM boosts the flow and coating of colored or stamped concrete, enabling detailed layouts with minimal breaking or surface area imperfections.

By boosting mechanical efficiency, sustainability, and cost-efficiency, Anionic Polyacrylamide Concrete Polymer Powder is an essential additive in modern-day construction, resolving difficulties from architectural stability to ecological compliance. Its versatility throughout diverse applications makes it crucial for designers and contractors aiming to optimize concrete performance.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Anionic Polyacrylamide Concrete Polymer Powder

What is Anionic Polyacrylamide Concrete Polymer Powder? Anionic Polyacrylamide (APAM) Concrete Polymer Powder is a water-soluble synthetic polymer used as an additive in concrete mixes. It acts as a binder, thickener, and flocculant, improving concrete’s workability, cohesion, and durability. Its anionic (negatively charged) nature helps disperse particles evenly, reduce water separation, and enhance the structural integrity of concrete.

What are the key benefits of using Anionic Polyacrylamide in concrete? APAM improves concrete performance by reducing water content without compromising workability, leading to higher compressive strength. It minimizes cracks, shrinkage, and dust formation, while enhancing adhesion between cement particles and aggregates. It also improves resistance to chemicals, abrasion, and weathering, making it ideal for foundations, pavements, and precast concrete exposed to harsh conditions.

How is Anionic Polyacrylamide Polymer Powder applied in concrete mixes? The powder is typically dosed at 0.1%–0.5% of cement weight. It’s first dissolved in water to form a solution, then mixed into the concrete during batching. Precise dosing and thorough mixing are critical to avoid clumping and ensure even distribution. Always follow manufacturer guidelines for optimal results.

Is Anionic Polyacrylamide safe to handle? While APAM is non-toxic once cured, the powder form requires careful handling. Direct inhalation or skin contact should be avoided. Use gloves, goggles, and masks during mixing. Store away from food and beverages, and rinse exposed skin immediately. Properly cured concrete containing APAM poses no health risks.

How should Anionic Polyacrylamide Powder be stored? Store in a cool, dry place in sealed original packaging to prevent moisture absorption. Avoid direct sunlight and high humidity, as clumping or degradation may occur. When stored correctly, it retains effectiveness for 12–24 months. Check for lumps or discoloration before use, and discard if compromised.

(Anionic Polyacrylamide Concrete Polymer Powder)