Overview of Di-TMP 98% Di-Trimethylolpropane for PVC Stabilizer

Specialty surfactants are a diverse class of surface-active agents designed for specific, high-performance applications where standard surfactants may not meet the required performance criteria. These surfactants are often tailor-made to exhibit unique properties, such as extreme temperature stability, low foam formation, high solubility in specific solvents, or compatibility with particular chemical systems. They are crucial components in formulations demanding precision, enhanced functionality, or strict regulatory compliance, found across industries from pharmaceuticals to advanced materials manufacturing.

Features of Di-TMP 98% Di-Trimethylolpropane for PVC Stabilizer

-

Customized Performance: Developed to meet exacting specifications, offering tailored functionalities beyond generic surfactants.

-

High Efficiency: Designed to work at lower concentrations or under challenging conditions, increasing performance per unit mass.

-

Unique Properties: May exhibit special traits such as non-flammability, low toxicity, high thermal stability, or specific solubility profiles.

-

Regulatory Compliance: Often formulated to meet stringent industry-specific regulations, such as food-grade, medical, or eco-friendly standards.

-

Innovative Chemistry: Incorporate novel chemistries, such as fluorinated, silicone-based, or bio-based structures, to achieve specialized performance.

-

Synergistic Effects: Frequently used in combination with other surfactants to enhance or augment performance in complex formulations.

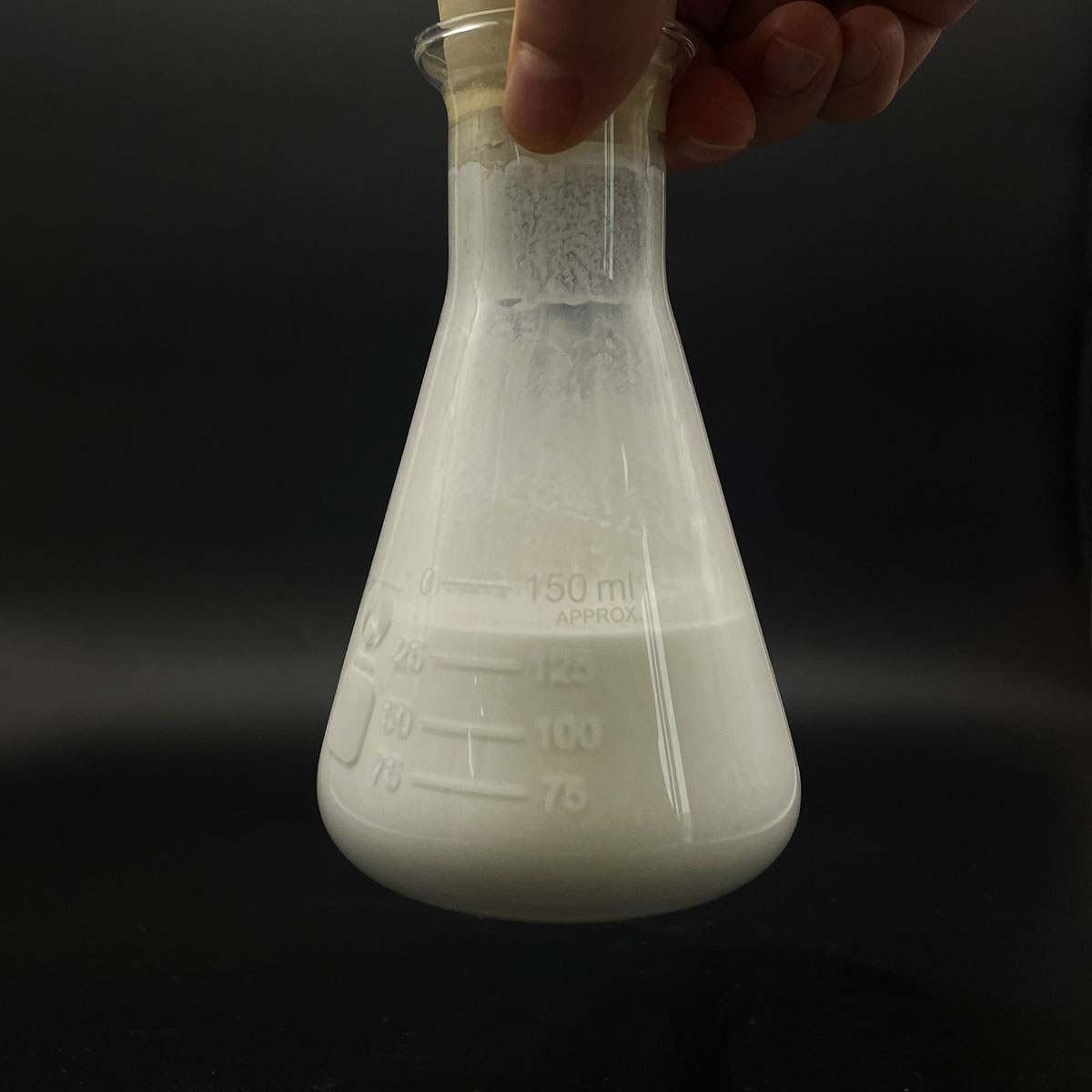

(Di-TMP 98% Di-Trimethylolpropane for PVC Stabilizer)

Specification of Di-TMP 98% Di-Trimethylolpropane for PVC Stabilizer

Di-Trimethylolpropane (Di-TMP) 98% is a high-purity, multifunctional natural substance extensively made use of as an essential part in PVC stabilizers. This item acts as a synergistic co-stabilizer, improving the thermal security and processing efficiency of PVC-based products. Its chemical framework, including 2 hydroxyl groups, makes it possible for efficient communication with metal-based stabilizers, boosting total performance and durability of PVC items.

Specs: .

– Chemical Name: Di-Trimethylolpropane.

– CAS Number: 23235-61-2.

– Molecular Formula: C7H14O3.

– Molecular Weight: 146.18 g/mol.

– Pureness: ≥ 98%.

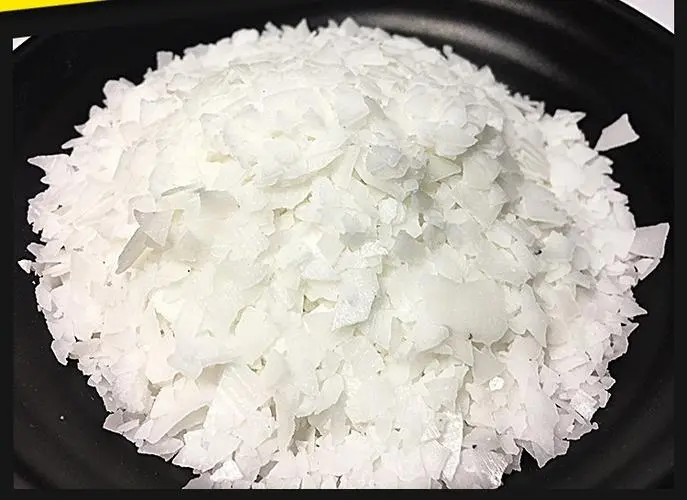

– Look: White crystalline powder or flakes.

– Solubility: Soluble in water and polar natural solvents (e.g., ethanol, acetone).

– Melting Point: 58– 62 ° C.

– Density: 1.1 g/cm ³ (approx.).

– Wetness Web content: ≤ 0.5%.

– Ash Web content: ≤ 0.1%.

– Service life: 24 months when kept in a cool, dry, aerated environment.

Secret Features: .

1. Thermal Stabilization: Di-TMP 98% effectively feeds on hydrochloric acid (HCl) launched during PVC degradation, decreasing staining and maintaining mechanical homes.

2. Collaborating Effect: Works with calcium-zinc (Ca-Zn) and other metal-based stabilizers to decrease steel chloride development, improving heat security and reducing plate-out.

3. Reduced Volatility: High thermal stability ensures very little dissipation during PVC processing, appropriate for high-temperature applications.

4. Compatibility: Easily spreads in PVC matrices, boosting product uniformity and surface area finish.

5. Eco-friendly: Sustains formulation of lead-free stabilizers, aligning with worldwide regulations.

Applications: .

Primarily utilized in PVC stabilizers for inflexible and adaptable PVC products, including pipelines, accounts, cables, movies, and synthetic natural leather. Suitable for extrusion, shot molding, and calendaring processes. Its capability to boost UV resistance and weatherability makes it suitable for exterior applications.

Handling & Storage space: .

Shop in secured containers far from wetness, straight sunshine, and inappropriate substances (strong acids/oxidizers). Use PPE (handwear covers, safety glasses) throughout managing to avoid irritability.

Regulatory Compliance: .

Complies with REACH, RoHS, and other international requirements. Safe and secure for industrial usage when dealt with properly.

Di-TMP 98% uses a cost-efficient option for enhancing PVC stability, making certain durability, and conference stringent efficiency requirements across industries.

(Di-TMP 98% Di-Trimethylolpropane for PVC Stabilizer)

Applications of Di-TMP 98% Di-Trimethylolpropane for PVC Stabilizer

Di-Trimethylolpropane (Di-TMP 98%) is a functional polyol substance widely made use of as a key component in PVC stabilizers, offering enhanced thermal stability, sturdiness, and processing performance. As a high-purity natural additive, Di-TMP 98% serves as a multifunctional agent in PVC solutions, dealing with challenges such as warm destruction, staining, and mechanical weak point throughout PVC processing and end-use applications. Its distinct chemical framework enables it to work as both a plasticizer and a stabilizer synergist, making it essential in creating high-performance PVC items.

Among the primary applications of Di-TMP 98% in PVC stablizing is its role in boosting thermal security. During PVC handling at elevated temperature levels, the polymer is prone to dehydrochlorination, leading to chain scission and discoloration. Di-TMP 98% efficiently feeds on hydrochloric acid (HCl), a result of thermal deterioration, by counteracting it with its hydroxyl groups. This minimizes the autocatalytic destruction process, expanding the handling window and maintaining the material’s shade clearness.

Additionally, Di-TMP 98% boosts the compatibility of metal-based stabilizers (e.g., calcium-zinc or organotin) with PVC matrices. It serves as a ligand, improving the dispersion of steel ions and lowering plate-out on equipment surface areas. This results in smoother handling, minimized tools wear, and consistent item high quality. The compound additionally adds to lasting stability by minimizing oxidative destruction, making sure PVC products maintain their mechanical residential properties and appearance under UV exposure or rough environmental conditions.

In flexible PVC applications, such as wires, floor covering, and automobile interiors, Di-TMP 98% improves adaptability and low-temperature resistance without endangering tensile toughness. Its reduced volatility guarantees marginal migration, boosting item long life. For inflexible PVC makes use of, including pipelines, accounts, and building and construction materials, it boosts influence resistance and weatherability.

In addition, Di-TMP 98% straightens with environment-friendly campaigns, as it is free from heavy steels and phthalates, conference governing requirements for safe stabilizers. Its efficiency at reduced focus decreases formula prices while maintaining performance.

In summary, Di-TMP 98% is an important additive for PVC stablizing, delivering thermal defense, mechanical reinforcement, and environmental compliance across sectors such as building and construction, vehicle, and electronic devices. Its multifunctional advantages make it a cost-efficient remedy for premium, resilient PVC items.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Di-TMP 98% Di-Trimethylolpropane for PVC Stabilizer

What is Di-TMP 98% (Di-Trimethylolpropane) and how is it used in PVC stabilizers?

Di-Trimethylolpropane (Di-TMP) 98% is a high-purity organic compound primarily used as a synergist in PVC stabilizer formulations. It enhances the thermal stability of PVC by interacting with metal-based stabilizers (e.g., calcium-zinc or lead-based systems), reducing degradation during processing. Its role includes scavenging acidic byproducts and improving long-term color retention in PVC products like pipes, cables, and profiles.

Why is Di-TMP 98% preferred in PVC stabilization?

Di-TMP 98% offers superior compatibility with PVC and stabilizer systems, ensuring even dispersion and efficient performance. Its high hydroxyl content enables effective neutralization of HCl released during PVC processing, delaying degradation. Unlike some alternatives, it minimizes plate-out (residue buildup on machinery) and maintains clarity in transparent PVC applications, making it ideal for high-quality, durable products.

What are the key benefits of using Di-TMP 98% in PVC formulations?

The compound improves thermal stability, extends processing time, and enhances UV resistance in finished PVC products. It also reduces discoloration and brittleness, ensuring consistent mechanical properties. Its low volatility at high temperatures prevents fogging, and its non-toxic nature makes it suitable for eco-friendly stabilizer systems, complying with regulations for food-contact or medical-grade PVC.

How is Di-TMP 98% incorporated into PVC stabilizer systems?

Di-TMP 98% is typically blended with primary stabilizers (e.g., metal soaps) and lubricants during PVC compounding. The recommended dosage ranges from 0.1% to 1.0% of the total formulation, depending on processing conditions and performance requirements. It is added during the dry mixing phase to ensure uniform distribution before extrusion or molding.

Are there handling or storage guidelines for Di-TMP 98%?

Store Di-TMP 98% in a cool, dry place away from moisture and direct sunlight. Use sealed containers to prevent contamination. When handling, wear standard PPE (gloves, goggles) to avoid skin or eye irritation. The product is stable under normal conditions but should be kept away from strong oxidizers. Shelf life is typically 24 months if stored properly.

(Di-TMP 98% Di-Trimethylolpropane for PVC Stabilizer)