Overview of Good Cationic Anionic Nonionic Polyacrylamide for Sewage Chemical

Nonionic surfactants are a class of surface-active agents that do not carry an electrical charge in aqueous solutions, distinguishing them from ionic surfactants like cationics and anionics. They are composed of a hydrophilic (water-loving) head group and a hydrophobic (oil-loving) tail, which allows them to reduce surface tension between fluids and facilitate interactions between substances that are normally immiscible. Their neutrality makes them stable over a wide pH range and compatible with other types of surfactants, making them highly versatile in numerous applications.

Features of Good Cationic Anionic Nonionic Polyacrylamide for Sewage Chemical

-

Neutral Charge: Lack of charge leads to compatibility with both anionic and cationic substances, reducing the risk of precipitation or instability in formulations.

-

Wide pH Stability: Function effectively across a broad pH range, making them suitable for diverse chemical environments.

-

Solubility: Readily soluble in both water and organic solvents, enhancing their utility in cleaning, emulsification, and dispersion processes.

-

Low Foam Profile: Many nonionic surfactants generate less foam compared to their ionic counterparts, beneficial in applications where excessive foam is undesirable.

-

Wetting and Spreading: Excellent at reducing surface tension, promoting wetting and spreading of liquids on surfaces, improving cleaning and coating processes.

-

Emulsification: Efficiently stabilize oil-in-water or water-in-oil emulsions, depending on their structure, which is crucial in formulations like cosmetics, agrochemicals, and food products.

(Good Cationic Anionic Nonionic Polyacrylamide for Sewage Chemical)

Specification of Good Cationic Anionic Nonionic Polyacrylamide for Sewage Chemical

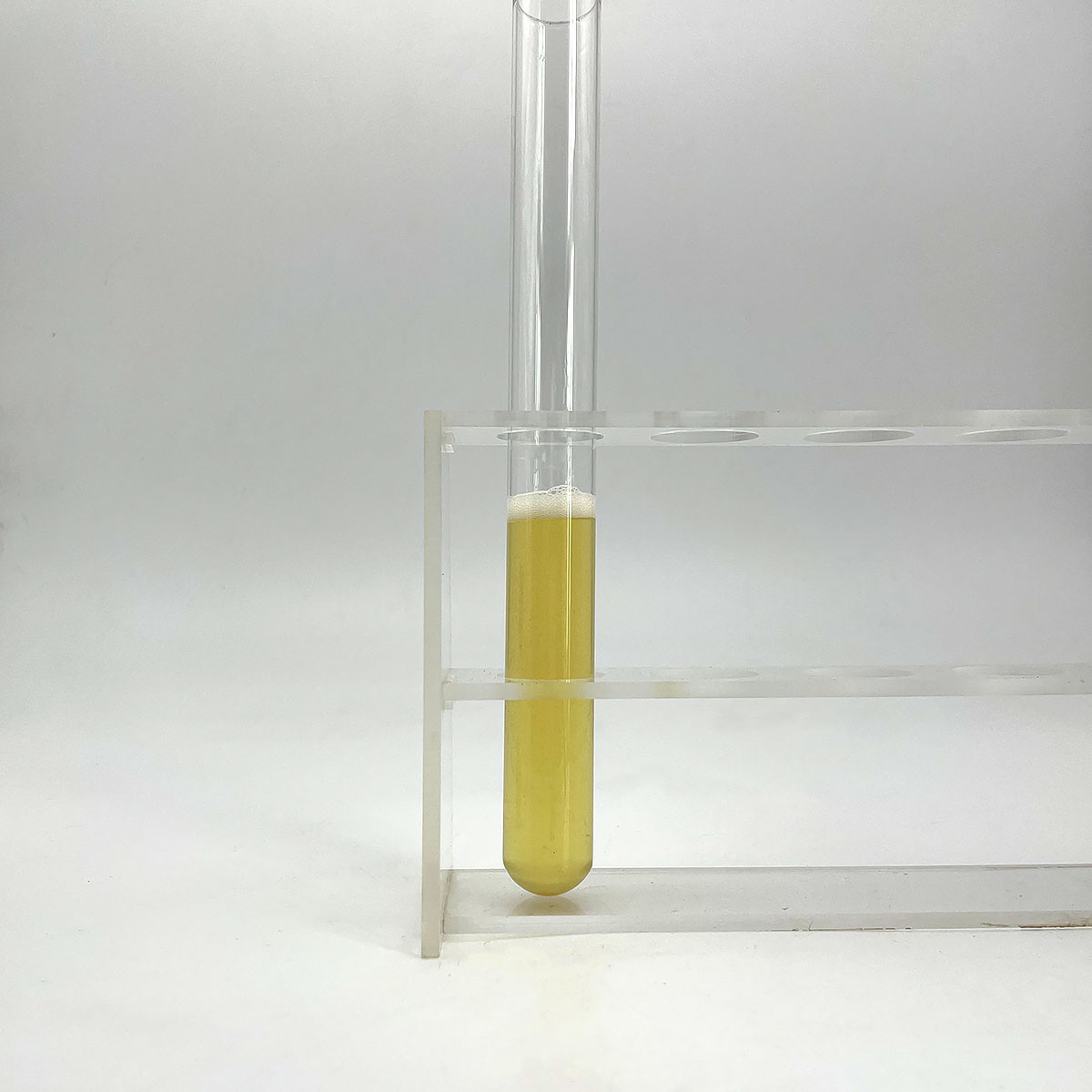

Excellent Cationic, Anionic, and Nonionic Polyacrylamide (PAM) are high-performance polymers widely utilized in sewage and wastewater treatment for effective solid-liquid separation, sludge dewatering, and flocculation. These polymers are tailored to address different wastewater structures, using flexibility in treating metropolitan, commercial, and chemical sewer. Below are the crucial specifications for each type:

** Cationic Polyacrylamide **: Defined by a positive cost, this kind is perfect for organic-rich sewage, such as metropolitan wastewater or biological sludge. It has a tool to high molecular weight (8– 12 million Daltons) and a fee thickness ranging from 10% to 60%. The polymer dissolves in water within 60 minutes, forming a viscous option. Efficient in pH 4– 10, it binds adversely charged bits by means of cost neutralization, improving sludge dewatering. Normal dose is 0.1– 5 ppm, depending on pollutant lots.

** Anionic Polyacrylamide **: With a negative charge, this variant master dealing with inorganic suspensions like mining or metallurgical wastewater. It includes a really high molecular weight (12– 20 million Daltons) and lower cost thickness (10– 40%). It dissolves in 60– 90 minutes and does ideally in neutral to alkaline conditions (pH 7– 14). Its lengthy molecular chains bridge bits, developing huge flocs. Dosage arrays from 0.5– 5 ppm, adapted to suspended solids focus.

** Nonionic Polyacrylamide **: Uncharged, this type is fit for facility or variable wastewater, consisting of acidic streams (pH 3– 10). Its moderate molecular weight (5– 8 million Daltons) and hydrogen-bonding mechanism enable adaptability. Dissolution takes 60– 90 mins. Dose ranges 0.2– 5 ppm, perfect for stabilizing solutions or dealing with oily sewage.

Typical specs consist of a white granular or powdered appearance, wetness material ≤ 10%, and recurring acrylamide ≤ 0.05% (meeting EPA and REACH safety and security requirements). All kinds are water-soluble, safe, and non-corrosive when handled correctly. Store in a trendy, dry environment (30 ° C, humidity 80%) to stop caking. Life span is 24 months in covered packaging. These polymers lower sludge volume, enhance purification efficiency, and adhere to ecological policies, ensuring economical, environmentally friendly sewer treatment. Constantly use protective gear throughout managing to avoid inhalation or call.

(Good Cationic Anionic Nonionic Polyacrylamide for Sewage Chemical)

Applications of Good Cationic Anionic Nonionic Polyacrylamide for Sewage Chemical

Cationic, anionic, and nonionic polyacrylamides (PAMs) are essential polymers in sewer and wastewater treatment, providing customized options for diverse pollutants. Their unique fee buildings allow efficient solid-liquid splitting up, sludge dewatering, and toxin elimination, making them essential for commercial and community applications.

** Cationic Polyacrylamide ** is positively charged, ideal for treating organic-rich wastewater. It masters binding adversely charged organic particles, such as those in local sewer, food processing, and fabric effluents. By neutralizing fees, it advertises coagulation and types thick flocs, improving sludge dewatering in centrifuges or filter presses. This minimizes sludge volume, lowering disposal costs. Industries like paper manufacturing and tanneries rely on cationic PAM to manage high organic tons and improve clarifier performance.

** Anionic Polyacrylamide ** carries a negative charge, making it reliable for not natural particles like clays, silts, and steel hydroxides. It is commonly utilized in mining wastewater to work out suspended solids during tailings therapy and mineral handling. In drinking water plants, it clarifies turbid water by accumulating fine bits. Anionic PAM also binds dissolved metal ions, helping in hefty steel elimination from commercial effluents. Its high molecular weight develops big flocs that resolve rapidly, enhancing sedimentation in community and chemical wastewater systems.

** Nonionic Polyacrylamide ** does not have charge, offering flexibility in neutral or variable pH conditions. It supports emulsions and puts on hold oils in petrochemical or mechanical wastewater. In agriculture, it prevents soil disintegration by binding bits in runoff water. Nonionic PAM adapts to complex wastewater with mixed impurities, serving as a flocculant in electronics or metallurgy markets where pH changes.

All three PAM kinds enhance treatment performance, lower functional expenses, and make sure conformity with environmental requirements. They are safe, non-toxic, and lessen chemical usage while boosting water reuse. By choosing the ideal PAM type, markets achieve optimum sludge administration, clearer effluent discharge, and lasting wastewater solutions.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Good Cationic Anionic Nonionic Polyacrylamide for Sewage Chemical

1. **What is the difference between cationic, anionic, and nonionic polyacrylamide?**

Cationic polyacrylamide carries a positive charge, ideal for binding negatively charged particles in organic sludge (e.g., municipal sewage). Anionic polyacrylamide has a negative charge, effective for flocculating inorganic materials like clay or metals in industrial wastewater. Nonionic polyacrylamide has no charge, suited for neutral or variable pH environments, often used in mineral processing or high-salinity water.

2. **How do I choose the right type for my sewage treatment?**

Select based on wastewater characteristics. Test the sludge’s charge (zeta potential), pH, and composition. Cationic is preferred for organic-heavy sewage, anionic for inorganic suspensions, and nonionic for complex or high-salt conditions. Lab jar tests or pilot trials are recommended to confirm compatibility and efficiency.

3. **What is the recommended dosage for polyacrylamide in sewage treatment?**

Dosage varies from 0.1–10 ppm, depending on contaminant concentration and sludge properties. Overdosing can reduce flocculation efficiency or increase costs. Start with a low dose (0.1–1 ppm), adjust incrementally, and monitor clarity, sedimentation speed, and sludge dewatering results.

4. **Is polyacrylamide safe to handle and store?**

Yes, but follow safety protocols. Use gloves and goggles to avoid skin/eye contact. Store in a cool, dry place away from moisture and direct sunlight. Keep sealed in original packaging to prevent clumping. Shelf life is typically 12–24 months if stored properly.

5. **What factors affect polyacrylamide’s performance in sewage treatment?**

Key factors include wastewater pH, temperature, ionic strength, mixing intensity, and contaminant type. High temperatures or extreme pH levels may degrade polymer efficiency. Incompatible charge densities or improper dissolution (e.g., incomplete stirring) can also reduce effectiveness. Pretesting under real conditions ensures optimal results.

(Good Cationic Anionic Nonionic Polyacrylamide for Sewage Chemical)