Overview of Oh Polymer Hydroxy Terminated Silicone Oil107 for RTV Rubber Material

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Oh Polymer Hydroxy Terminated Silicone Oil107 for RTV Rubber Material

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

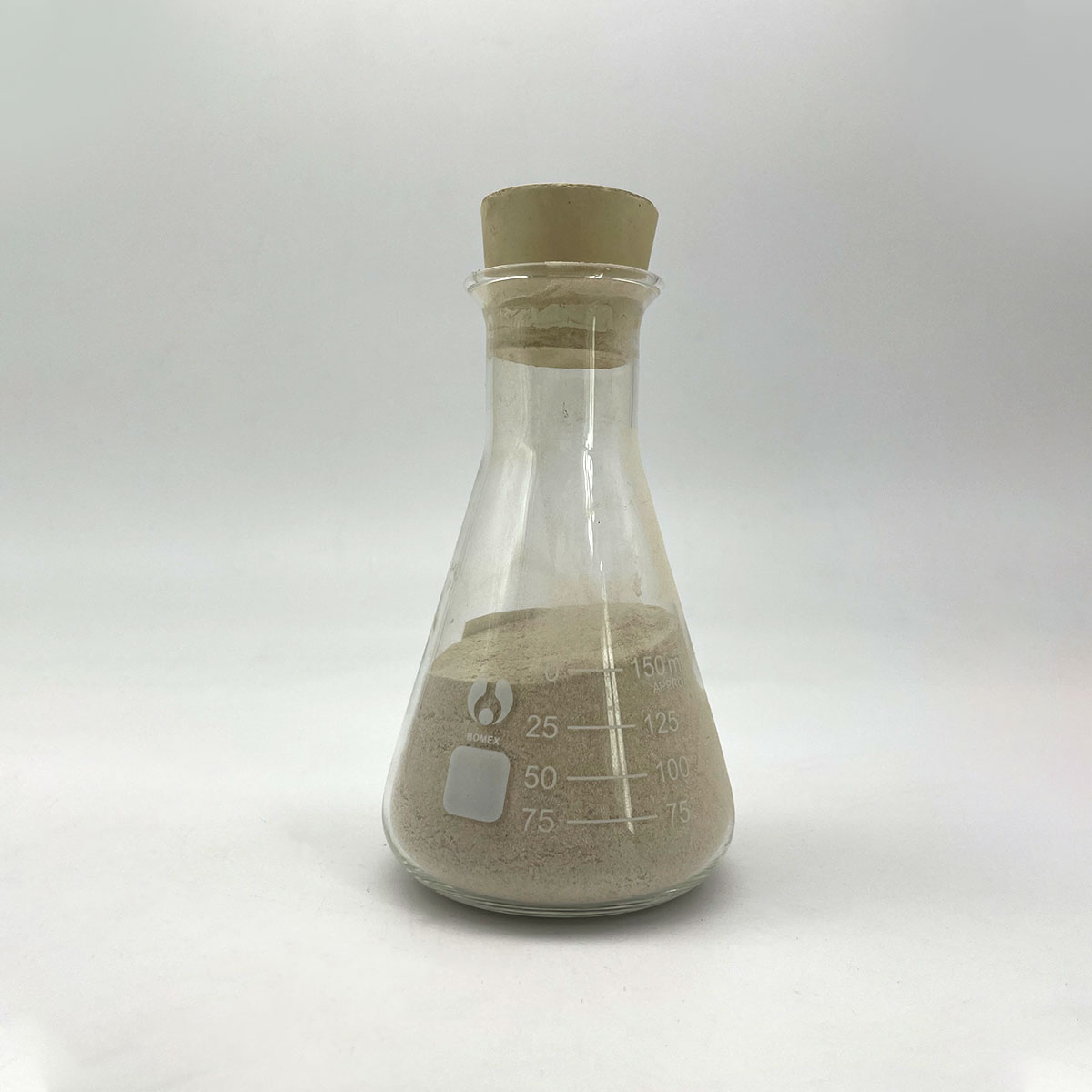

(Oh Polymer Hydroxy Terminated Silicone Oil107 for RTV Rubber Material)

Specification of Oh Polymer Hydroxy Terminated Silicone Oil107 for RTV Rubber Material

Oh Polymer Hydroxy Terminated Silicone Oil107 is a specialized silicone fluid designed for usage in RTV (Space Temperature Vulcanizing) rubber formulas. It serves as a reactive intermediate, crosslinker, or modifier to enhance the efficiency of silicone-based elastomers. The item is identified by its hydroxy-terminated framework, which allows compatibility with a wide range of silicone polymers and fillers. Below are the essential requirements and applications of this material:

** Chemical Composition **: Hydroxy-terminated polydimethylsiloxane (PDMS) with a linear molecular framework. The hydroxy (-OH) teams at both ends of the silicone chain help with crosslinking responses with various other useful silanes or polymers in RTV systems.

** Physical Properties **: The silicone oil has a clear, colorless look with a viscosity variety of 500– 2000 mPa · s (at 25 ° C), relying on molecular weight. Its hydroxy content usually ranges between 0.5% and 1.5% by weight, making certain reliable sensitivity. The density is about 0.97– 1.00 g/cm ³, and it exhibits a low pour factor (-50 ° C), making it ideal for low-temperature applications. The flash factor surpasses 200 ° C, guaranteeing thermal security throughout handling.

** Functional Benefits **: When included right into RTV rubber, this silicone oil boosts mechanical buildings such as flexibility, tensile stamina, and prolongation. It boosts attachment to substrates like steels, plastics, and glass while preserving adaptability across a large temperature array (-60 ° C to 200 ° C). The hydroxy groups enable moisture-curing behavior, allowing the RTV product to vulcanize at space temperature level upon direct exposure to climatic moisture.

** Compatibility **: Suitable with common RTV parts, consisting of fumed silica, calcium carbonate, and alkoxy silanes (e.g., methyltrimethoxysilane). It can be blended with various other silicone fluids or resins to adjust rheology and remedy speed.

** Applications **: Suitable for high-performance RTV sealers, adhesives, and potting compounds in auto, electronic devices, and building markets. It is used in gaskets, insulation coatings, and mold-making applications requiring resistance to UV, ozone, and chemicals.

** Storage & Handling **: Shop in an amazing, completely dry area far from wetness to stop early crosslinking. Usage secured containers to lessen exposure to humidity. Service life is year when stored effectively.

This silicone oil meets sector requirements for non-toxicity and environmental safety and security, with low volatile natural compound (VOC) discharges. It is developed to optimize processing effectiveness and end-product sturdiness in RTV rubber systems.

(Oh Polymer Hydroxy Terminated Silicone Oil107 for RTV Rubber Material)

Applications of Oh Polymer Hydroxy Terminated Silicone Oil107 for RTV Rubber Material

Oh Polymer Hydroxy Ended Silicone Oil107 is a versatile silicone-based intermediate widely used in the formulation of Room Temperature Vulcanizing (RTV) rubber materials. Its hydroxy-terminated structure makes it possible for responsive cross-linking with silanol or alkoxy-functional elements, making it a critical additive for improving the performance and handling of silicone rubber items. Below are key applications of this polymer in RTV rubber materials:

1. ** Sealants and Adhesives **: The hydroxy-terminated silicone oil functions as a plasticizer and responsive modifier in RTV silicone sealers and adhesives. It boosts adaptability, adhesion, and elongation while keeping thermal stability (-50 ° C to 200 ° C). Its compatibility with fillers and cross-linkers ensures uniform healing at space temperature, making it perfect for construction, automobile, and aerospace applications calling for durable, weather-resistant seals.

2. ** Flexible Molds and Casting **: In RTV rubber mold and mildews for art, prototyping, or commercial casting, this silicone oil improves flowability and minimizes viscosity throughout processing. It guarantees smooth demolding and high replication accuracy while giving tear resistance and long-term resilience, even under duplicated stress.

3. ** Digital Encapsulation **: RTV silicones formulated with OH Polymer 107 are utilized to secure sensitive electronic components from wetness, dirt, and thermal shock. The polymer’s stability and electrical insulation residential properties make sure reliable efficiency in potting compounds, gaskets, and conformal coatings for circuits, LEDs, and sensors.

4. ** High-Performance Coatings **: The oil’s hydroxy reactivity enables it to bond with substratums, enhancing layer attachment and adaptability. It is utilized in anti-corrosive, water-proof, and UV-resistant finishings for commercial tools, marine surface areas, and exterior structures.

5. ** Medical and Food-Grade Applications **: When cleansed, hydroxy-terminated silicone oil contributes to medical-grade RTV silicones for tubing, seals, and implants. Its biocompatibility and resistance to sterilization procedures (autoclaving, UV) make it suitable for FDA-compliant applications.

** Benefits **: OH Polymer 107 boosts RTV rubber’s mechanical strength, thermal stability, and chemical resistance. It decreases shrinkage during treating and makes sure regular viscosity for easier handling. Its compatibility with ingredients like silica, pigments, and flame resistants permits customized solutions for diverse markets.

In recap, Oh Polymer Hydroxy Terminated Silicone Oil107 is indispensable for developing high-grade RTV silicones, using versatility, durability, and precision across sealers, electronics, layers, and clinical applications. Its responsive hydroxy teams enable robust cross-linking, making sure products satisfy rigorous performance requirements.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Oh Polymer Hydroxy Terminated Silicone Oil107 for RTV Rubber Material

(Oh Polymer Hydroxy Terminated Silicone Oil107 for RTV Rubber Material)