Overview of Paper-Making Chemicals Anionic Polyacrylamide Apam

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Paper-Making Chemicals Anionic Polyacrylamide Apam

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

(Paper-Making Chemicals Anionic Polyacrylamide Apam)

Specification of Paper-Making Chemicals Anionic Polyacrylamide Apam

Anionic Polyacrylamide (APAM) is a high-performance water-soluble polymer commonly utilized in the paper-making market as a retention aid, flocculant, and drain help. It improves paper high quality, improves retention of fines and fillers, and maximizes drain performance. Below are the key specifications and attributes of APAM for paper-making applications:

** Physical Residences **.

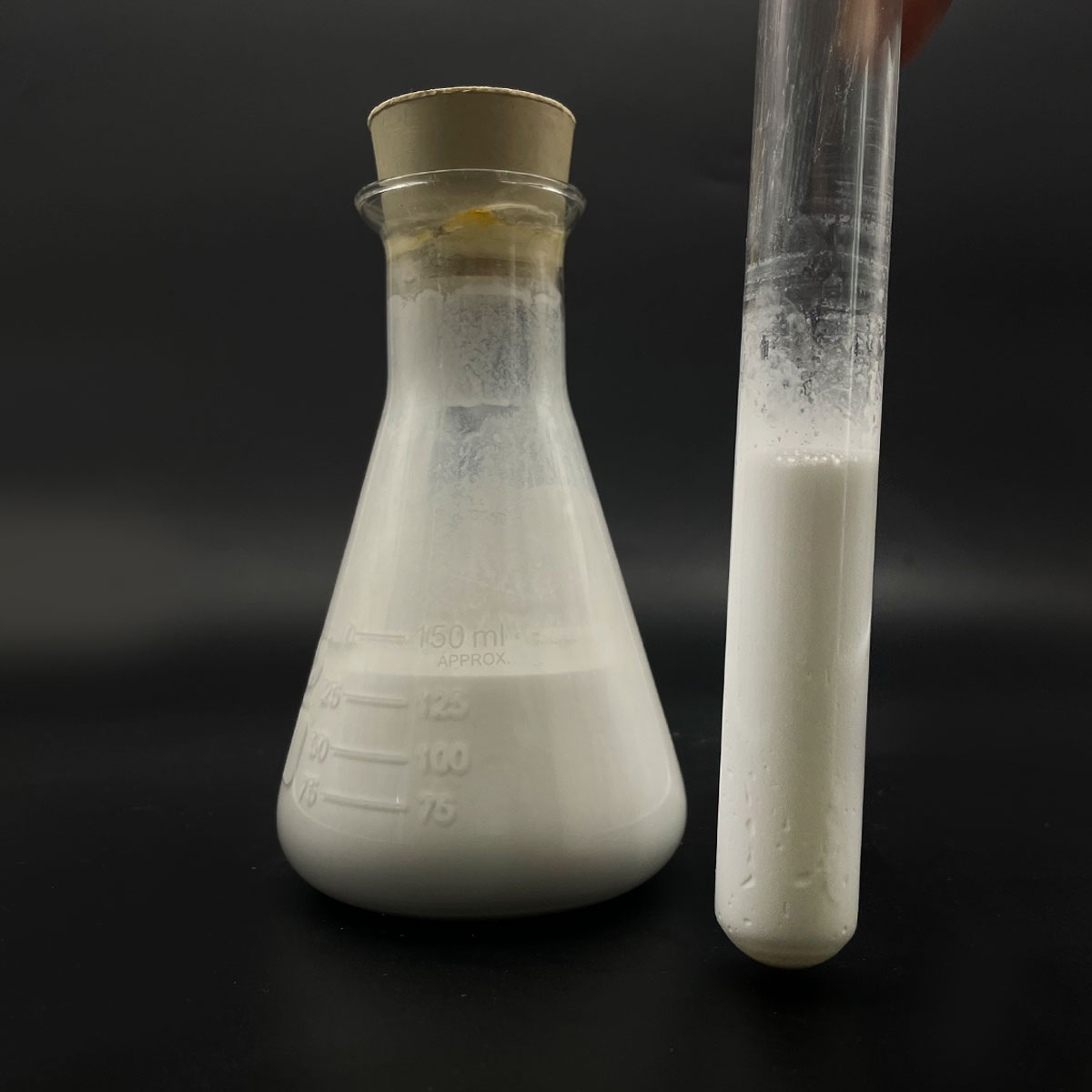

– ** Look **: White granular or great powder.

– ** Molecular Weight **: 8– 25 million Daltons (adjustable based on application).

– ** Ionic Fee **: Anionic (cost thickness flexible in between 10– 40%).

– ** Solubility **: Quickly soluble in water, creating a thick option.

– ** pH Stability **: Effective in pH 4– 10.

** Secret Features **.

– ** Retention & Drain Aid **: Improves retention of penalties, fillers, and ingredients (e.g., TiO ₂, CaCO ₃), improving return and decreasing resources prices.

– ** Boosted Water Drainage **: Increases dewatering on the cord section, enhancing maker speed and power effectiveness.

– ** Improved Sheet Development **: Advertises consistent fiber distribution, boosting paper level of smoothness, stamina, and printability.

– ** Minimized BOD/COD **: Lowers ecological effect by minimizing organic lots in wastewater.

** Applications in Paper-Making **.

– ** Product packaging Qualities **: Enhances stamina and stiffness in corrugated boards.

– ** Tissue & Towel **: Improves gentleness and bulk.

– ** Fine Paper **: Boosts printability and surface area smoothness.

** Usage Guidelines **.

– ** Dosage **: 0.1– 1.0 kg/ton of pulp (varies based upon furnish and process conditions).

– ** Preparation **: Pre-dissolve in water (0.1– 0.5% focus) prior to adding to the stock.

** Product packaging & Storage space **.

– ** Product packaging **: 25 kg woven bags with internal PE liner.

– ** Life span **: 24 months in an awesome, completely dry area (< 30 ° C).

** Compliance **: Fulfills ISO 9001, ISO 14001, and REACH criteria. Safe, non-hazardous.

(Paper-Making Chemicals Anionic Polyacrylamide Apam)

Applications of Paper-Making Chemicals Anionic Polyacrylamide Apam

Anionic Polyacrylamide (APAM) is a crucial chemical additive in the paper-making sector, playing an essential role in enhancing manufacturing efficiency and product high quality. As a high-molecular-weight polymer, APAM is extensively used for its exceptional flocculation, retention, and water drainage residential properties. Below are crucial applications of APAM in paper manufacturing:

** 1. Retention and Drain Aid **.

APAM enhances retention of great fragments, fillers, and fibers during paper development. By binding penalties and fillers, it enhances retention rates, minimizes material waste, and enhances drainage on the paper device. This causes faster dewatering, lowered energy consumption, and greater production speeds.

** 2. Strength Enhancement **.

APAM enhances paper by promoting fiber-to-fiber bonding. This boosts tensile stamina, tear resistance, and total sturdiness of the end product, making it perfect for product packaging, tissues, and specialized documents.

** 3. Effluent Therapy **.

In wastewater treatment, APAM help in flocculating suspended solids and raw material, guaranteeing compliance with environmental laws. It reduces sludge volume and makes clear water for reuse or secure discharge.

** 4. Coating and Sizing **.

APAM boosts finishing formulas by boosting pigment retention, level of smoothness, and printability. It also works as a sizing agent to regulate water absorption and ink penetration.

** 5. Price Performance **.

By maximizing raw material usage and minimizing wastewater treatment prices, APAM reduces total production expenses while improving item quality.

In recap, Anionic Polyacrylamide (APAM) is crucial in contemporary paper production, delivering effectiveness, sustainability, and high-performance paper items. Its flexibility and cost-effectiveness make it a foundation of the paper market.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Paper-Making Chemicals Anionic Polyacrylamide Apam

**5 FAQs of Paper-Making Chemicals: Anionic Polyacrylamide (APAM)**

**1. What is Anionic Polyacrylamide (APAM), and what role does it play in paper-making?**

Anionic Polyacrylamide (APAM) is a water-soluble polymer used in paper-making as a retention aid, flocculant, and drainage aid. It enhances fiber retention, improves drainage efficiency, and strengthens paper quality by binding fine particles and fillers.

**2. Why is APAM preferred in paper-making processes?**

APAM improves retention of fine particles and fillers (like calcium carbonate), reduces raw material waste, and enhances paper strength. It also optimizes drainage on paper machines, leading to faster production speeds and energy savings.

**3. How does APAM work in the paper-making process?**

APAM acts as a flocculant, binding fine particles and fillers into larger aggregates. This improves retention on the paper web and enhances dewatering during sheet formation. The result is better sheet formation, uniformity, and reduced effluent turbidity.

**4. What factors influence APAM dosage in paper-making?**

Dosage depends on factors like pulp type, filler content, water hardness, and process pH. Overdosing can cause over-flocculation, while under-dosing reduces retention. Optimal dosing requires lab trials and real-time monitoring.

**5. Is APAM environmentally safe?**

APAM is non-toxic and biodegradable under controlled conditions. However, excessive discharge into water bodies can affect aquatic ecosystems. Proper treatment of effluent and adherence to local regulations are crucial for sustainable use.

(Paper-Making Chemicals Anionic Polyacrylamide Apam)