Overview of Polyacrylamide Flocculant for Textile Wastewater Treatment – Anionic/Cationic/Non-Ionic

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Polyacrylamide Flocculant for Textile Wastewater Treatment – Anionic/Cationic/Non-Ionic

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

(Polyacrylamide Flocculant for Textile Wastewater Treatment – Anionic/Cationic/Non-Ionic)

Specification of Polyacrylamide Flocculant for Textile Wastewater Treatment – Anionic/Cationic/Non-Ionic

Polyacrylamide (PAM) flocculants are high-performance water-soluble polymers commonly utilized in fabric wastewater treatment to eliminate suspended solids, dyes, and organic toxins. Readily available in anionic, cationic, and non-ionic forms, these flocculants enhance solid-liquid splitting up by agglomerating great bits into bigger flocs, enhancing sedimentation, filtration, and clearness. Below are key requirements and applications for each type.

** Anionic Polyacrylamide **: Defined by an unfavorable cost, anionic PAM is perfect for dealing with wastewater with positively charged colloidal fragments, such as inorganic clays or steel hydroxides. It has a high molecular weight (5– 20 million Daltons) and a hydrolysis degree of 10– 30%, allowing efficient connecting and adsorption. Reliable in neutral to alkaline problems (pH 6– 10), it is commonly used in coagulation-flocculation processes with aluminum or iron salts. Dosage ranges from 0.1– 5 ppm, depending on pollutant load.

** Cationic Polyacrylamide **: Favorably charged cationic PAM masters reducing the effects of adversely charged organic matter, such as dyes, surfactants, and sludge. With a molecular weight of 3– 15 million Daltons and fee thickness of 5– 50% (depending upon alternative degree), it performs ideally in acidic to neutral environments (pH 3– 8). It is particularly effective in sludge dewatering, minimizing moisture material, and boosting filtration performance. Common dose is 0.5– 10 ppm.

** Non-Ionic Polyacrylamide **: Non-ionic PAM does not have charge and depends on hydrogen bonding and van der Waals forces for flocculation. Suitable for wastewater with low ionic strength or variable pH (2– 12), it is effective for supporting emulsions or treating effluents with blended impurities. Molecular weight arrays from 3– 15 million Daltons. Dosage ranges 0.2– 8 ppm.

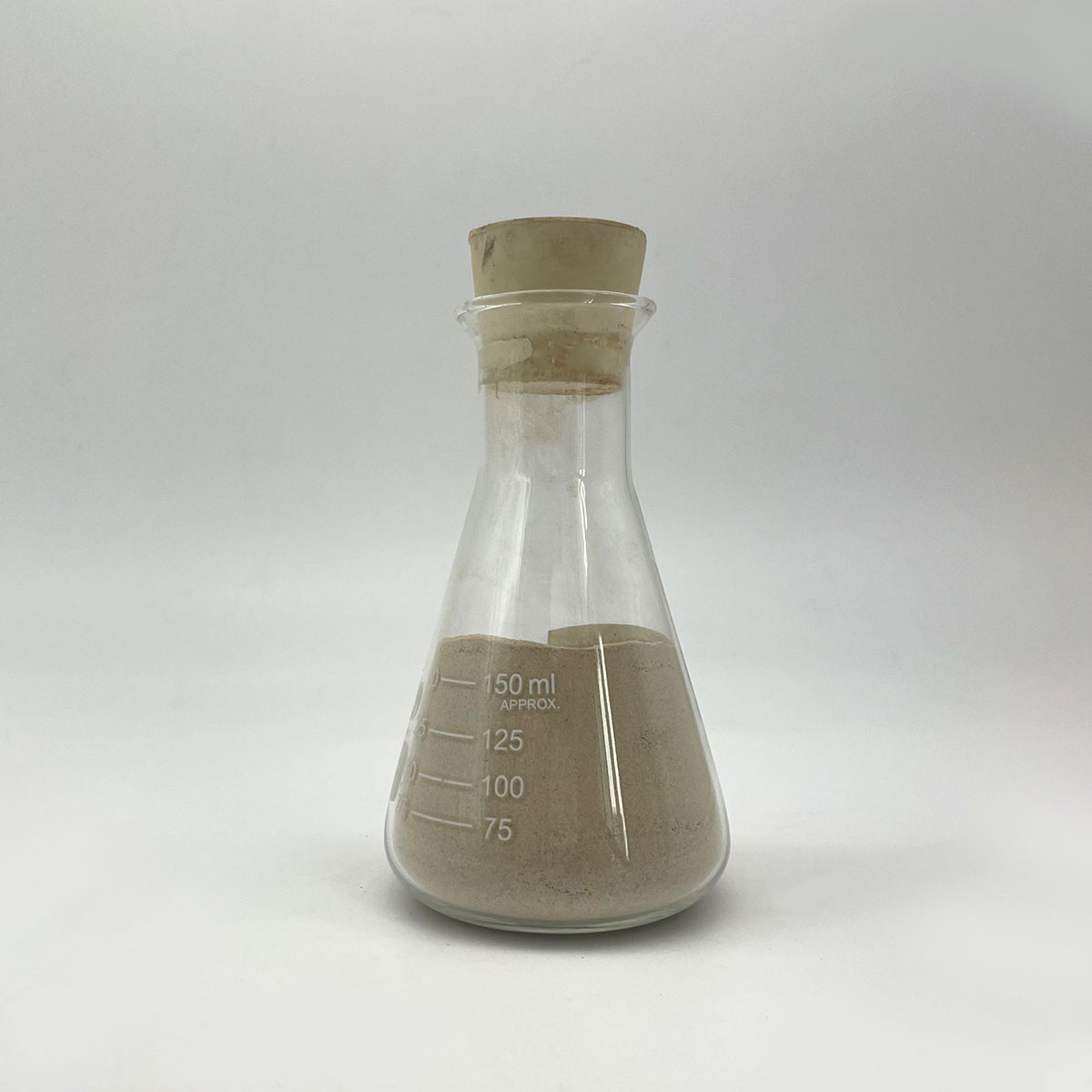

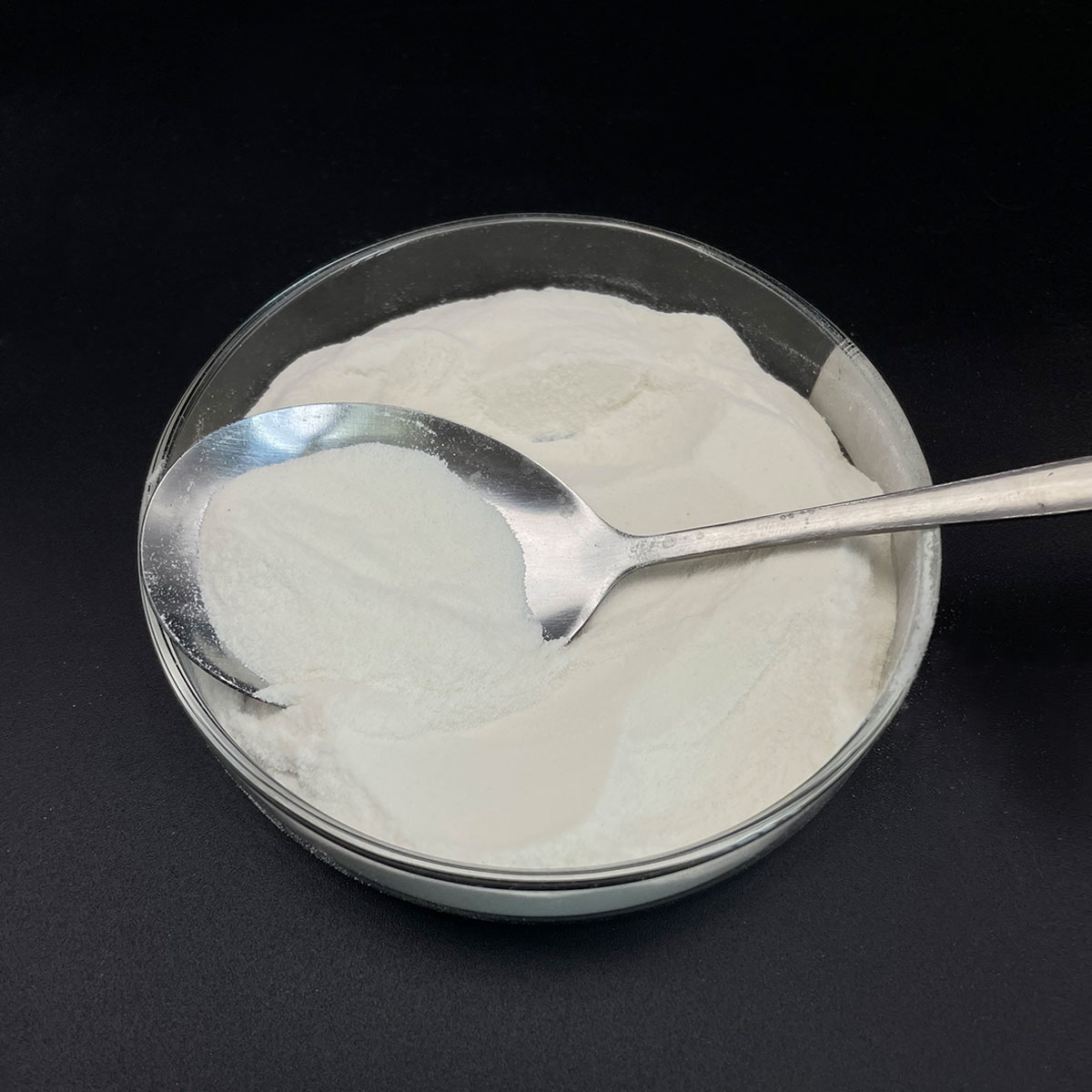

All kinds are provided as white powder or granules with ≥ 90% solubility in water, liquifying within 30– 90 minutes. Storage suggestions consist of amazing, completely dry conditions (below 25 ° C) in sealed product packaging to stop wetness absorption. Safety and security protocols advise utilizing PPE during taking care of to avoid inhalation or get in touch with.

Applications include main sedimentation, sludge thickening, and dye elimination. Advantages consist of reduced chemical oxygen demand (COD), boosted water clarity, and cost-effective sludge administration. Custom solutions are available to attend to details wastewater features, making sure conformity with environmental discharge criteria. Polyacrylamide flocculants provide a lasting, effective remedy for textile wastewater challenges.

(Polyacrylamide Flocculant for Textile Wastewater Treatment – Anionic/Cationic/Non-Ionic)

Applications of Polyacrylamide Flocculant for Textile Wastewater Treatment – Anionic/Cationic/Non-Ionic

Polyacrylamide (PAM) flocculants are extensively utilized in fabric wastewater therapy because of their extraordinary capacity to eliminate suspended solids, organic dyes, and chemical deposits. Offered in three primary kinds– anionic, cationic, and non-ionic– these polymers address diverse wastewater difficulties via tailored charge interactions and molecular structures.

** Anionic Polyacrylamide ** is effective in treating wastewater with high inorganic content, such as clay or steel hydroxides. Its negatively charged chains bind to favorably billed bits using hydrogen bonding and electrostatic destination, forming huge flocs that work out quickly. It is usually coupled with coagulants like aluminum sulfate or ferric chloride to reduce the effects of charges and boost sedimentation. Anionic PAM is optimal for eliminating colloidal particles and decreasing chemical oxygen need (COD) in coloring and publishing wastewater.

** Cationic Polyacrylamide ** excels in treating organic-rich wastewater, such as effluents including reactive dyes, starches, or synthetic sizing agents. The positively charged polymer reduces the effects of adversely charged organic molecules and colloidal materials, advertising aggregation. This makes it particularly helpful for sludge dewatering, as it enhances filterability and minimizes moisture web content in sludge. Cationic PAM additionally addresses color removal by binding to anionic dyes, making certain compliance with discharge guidelines.

** Non-Ionic Polyacrylamide ** operates through hydrogen bonding and van der Waals pressures, making it versatile for wastewater with variable pH or high salinity. It is effective in circumstances where ionic toughness or temperature level variations destabilize various other flocculants. Non-ionic PAM is frequently utilized to deal with combined waste streams including both natural and inorganic impurities, such as wastewater from material softening or finishing procedures.

All 3 types improve therapy efficiency by speeding up solid-liquid splitting up, minimizing sludge quantity, and improving water clearness. Their application reduces operational costs by minimizing chemical use and power intake. In addition, polyacrylamide flocculants are environmentally safe when used appropriately, weakening right into safe byproducts.

In summary, selecting the appropriate PAM type depends on wastewater composition, fee communications, and procedure needs. Anionic, cationic, and non-ionic polyacrylamides jointly use a durable service for textile industries aiming to satisfy ecological criteria while optimizing wastewater management.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Polyacrylamide Flocculant for Textile Wastewater Treatment – Anionic/Cationic/Non-Ionic

1. **What is polyacrylamide flocculant, and how does it work in textile wastewater treatment?**

Polyacrylamide (PAM) flocculants are water-soluble polymers used to separate suspended solids, dyes, and chemicals from textile wastewater. They work by binding particles through charge neutralization (ionic types) or bridging (non-ionic), forming larger clumps (flocs) that settle or float for easy removal. Anionic PAM targets positively charged contaminants, cationic PAM binds negatively charged organics, and non-ionic PAM works in pH-sensitive or low-ion environments.

2. **How do I choose between anionic, cationic, or non-ionic polyacrylamide?**

The choice depends on wastewater composition. Cationic PAM is ideal for organic sludge (e.g., dyes, proteins) due to its positive charge neutralizing negative contaminants. Anionic PAM suits inorganic-heavy wastewater (clay, metals) with positive particles. Non-ionic PAM is used when pH varies widely or ionic strength is low, as it relies on hydrogen bonding rather than charge. Lab tests (jar tests) determine the optimal type and dosage.

3. **What are the advantages of using PAM flocculants over other treatments?**

PAMs offer high efficiency at low doses, reducing sludge volume and treatment costs. They work rapidly, improve water clarity, and are adaptable to diverse wastewater conditions. Their versatility (anionic/cationic/non-ionic) allows customization, and they’re compatible with other treatments like coagulants. They also minimize chemical residue, supporting eco-friendly discharge compliance.

4. **How is polyacrylamide applied in textile wastewater systems?**

PAM is typically diluted to 0.1–0.5% solution and injected into wastewater streams. Mixing speed and time are critical: rapid mixing disperses the polymer, while slow mixing promotes floc growth. Overdosing can cause re-stabilization of particles, so dosing pumps and monitoring systems ensure precision. Post-treatment, flocs are removed via sedimentation, flotation, or filtration.

5. **Is polyacrylamide safe for the environment and human health?**

When used as directed, PAM is safe. It’s non-toxic, and the flocculated sludge can often be dewatered and disposed of safely. However, acrylamide monomer residues (a neurotoxin) must meet regulatory limits (0.05% in products). Proper handling (gloves, masks) is advised during preparation. Most PAMs are biodegradable under specific conditions, but compliance with local environmental guidelines is essential.

(Polyacrylamide Flocculant for Textile Wastewater Treatment – Anionic/Cationic/Non-Ionic)