Overview of Polyol/Polyether Polyol/Polymer Polyol /Hot Polyol/ Polyol in Good

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Polyol/Polyether Polyol/Polymer Polyol /Hot Polyol/ Polyol in Good

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Polyol/Polyether Polyol/Polymer Polyol /Hot Polyol/ Polyol in Good )

Specification of Polyol/Polyether Polyol/Polymer Polyol /Hot Polyol/ Polyol in Good

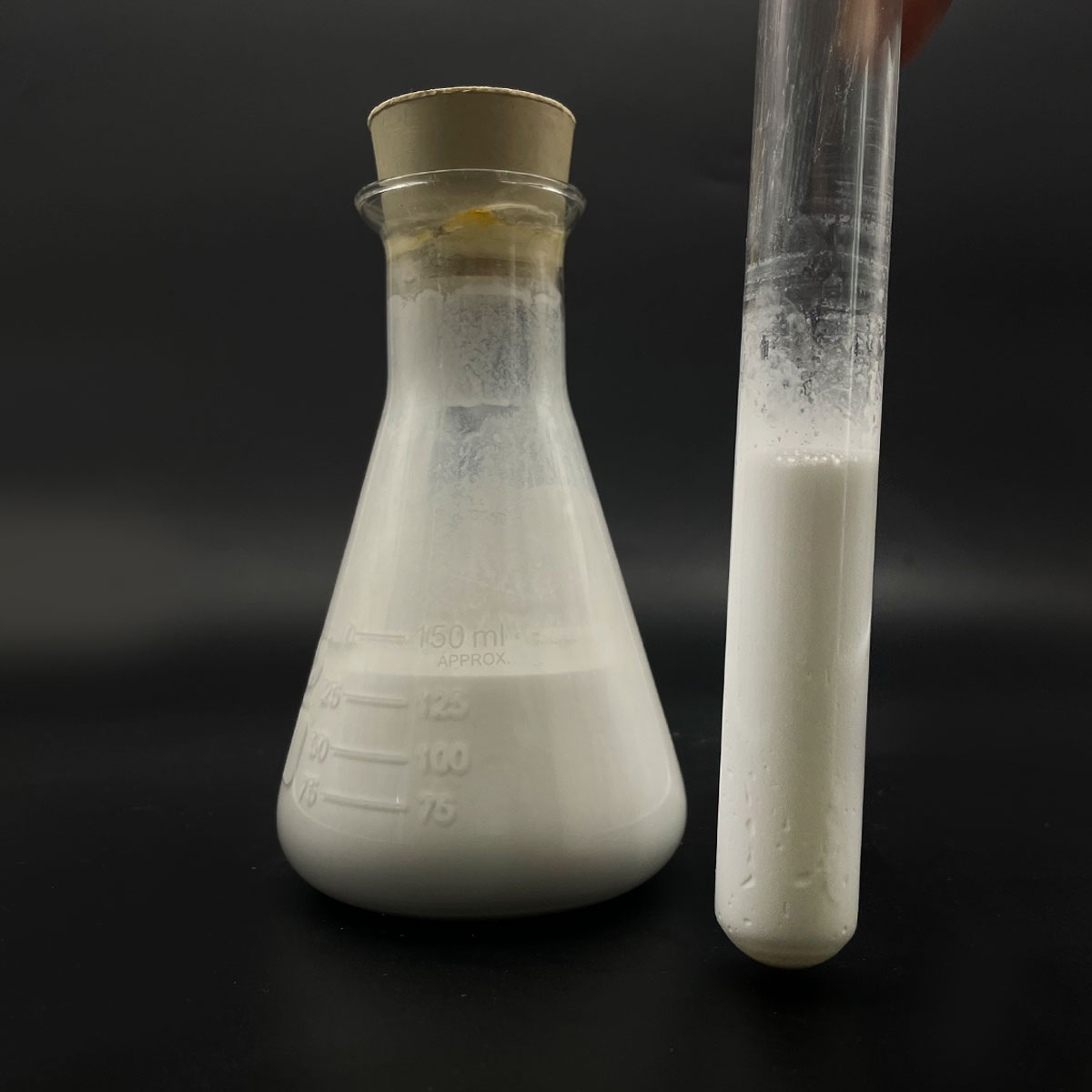

Polyols, including Polyether Polyol, Polymer Polyol, Hot Polyol, and common Polyol, are vital elements in polyurethane production. Their specifications vary based on application and chemical structure. ** Polyol (General): ** Generally identified by hydroxyl number (OH #) ranging from 20– 800 mg KOH/g, viscosity in between 200– 10,000 mPa · s at 25 ° C, and molecular weights from 1,000– 12,000 g/mol. Dampness web content is maintained below 0.1% to stop side responses. Applications consist of versatile foams, coverings, adhesives, and elastomers. ** Polyether Polyol: ** Produced via alkoxylation of starter particles (e.g., glycerol, sucrose). Functions low viscosity (200– 6,000 mPa · s), OH # of 20– 500 mg KOH/g, and high key hydroxyl web content for faster reactivity. Suitable for versatile foam, mattresses, and vehicle seating. ** Polymer Polyol: ** A dispersion of styrene-acrylonitrile (SAN) or polyurea bits in polyol. Solids material arrays 10– 50%, improving load-bearing buildings in high-resilience foams. Thickness is greater (1,500– 15,000 mPa · s )with OH # of 20– 35 mg KOH/g. Used in vehicle interiors and furniture. ** Hot Polyol: ** Developed for high-temperature processing (as much as 130 ° C), with thermal security made certain by low volatile web content (

(Polyol/Polyether Polyol/Polymer Polyol /Hot Polyol/ Polyol in Good )

Applications of Polyol/Polyether Polyol/Polymer Polyol /Hot Polyol/ Polyol in Good

Polyols, including Polyether Polyol, Polymer Polyol, and Hot Polyol, are flexible chemical substances commonly utilized as key resources in polyurethane manufacturing. Their distinct residential properties, such as adaptability, sturdiness, and thermal security, make them indispensable across industries. Here’s a review of their applications:

** Polyether Polyol ** is mostly used to manufacture flexible polyurethane foams, which are crucial in furniture, bed mattress, and auto seats because of their convenience and resilience. Its reduced thickness and compatibility with ingredients additionally make it excellent for elastomers, adhesives, and finishings. In building, polyether-based stiff foams give exceptional insulation for walls, roofing systems, and refrigeration systems, improving energy effectiveness.

** Polymer Polyol ** improves the load-bearing capability and hardness of polyurethane foams. It is extensively used in high-resilience foam applications, such as auto seats, armrests, and headrests, where durability and vibration resistance are crucial. The footwear industry counts on polymer polyols for midsole foams in tennis shoes, using light-weight padding. Additionally, it boosts the structural honesty of synthetic natural leather and industrial rollers.

** Hot Polyol ** refers to polyols refined at raised temperature levels, accelerating response times in polyurethane systems. This makes them perfect for stiff foam applications needing fast healing, such as spray foam insulation for buildings and refrigeration units. Hot polyols are also made use of in automobile components, like dashboards and bumpers, where fast production cycles and dimensional security are vital. Their thermal efficiency benefits commercial adhesives and finishings that must hold up against high-temperature settings.

Beyond conventional uses, polyols contribute to lasting solutions. Bio-based polyols derived from renewable energies like soybeans or castor oil are acquiring grip in environment-friendly foams and coverings. In the textile sector, polyol-based spandex fibers provide stretchability in sportswear and activewear. Electronics benefit from polyurethane encapsulants made with polyols, securing components from wetness and mechanical stress and anxiety.

On the whole, the flexibility of polyols drives technology comfortably, energy performance, and sustainability. From day-to-day things like mattresses and footwear to sophisticated applications in eco-friendly building and vehicle design, polyols play an essential function in enhancing item efficiency while aligning with global sustainability objectives. Their proceeded evolution makes certain importance in arising innovations and eco-conscious markets.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Polyol/Polyether Polyol/Polymer Polyol /Hot Polyol/ Polyol in Good

Polyol is a key component in polyurethane production, serving as the primary hydroxyl-rich compound that reacts with isocyanates to form polymers. It’s used in flexible and rigid foams, adhesives, coatings, and elastomers. Polyols are typically derived from petrochemicals or renewable resources like vegetable oils, offering versatility in applications ranging from insulation to automotive seating.

Polyether polyol and polymer polyol differ in structure and function. Polyether polyol is synthesized by reacting ethylene or propylene oxide with initiators, yielding materials ideal for flexible foams due to their elasticity. Polymer polyol, a modified version, contains dispersed polymer particles (like styrene-acrylonitrile) within a polyether base, enhancing load-bearing properties. This makes it suitable for high-resilience foams in mattresses and automotive interiors.

Hot polyol refers to polyols processed or stored at elevated temperatures (typically 40–60°C) to maintain low viscosity, ensuring smooth handling during manufacturing. Preheating improves reaction efficiency in rigid foam production, such as insulation panels, by accelerating curing and enhancing cell structure. This method is critical for large-scale industrial applications requiring precise temperature control.

Polymer polyols are primarily used in high-performance polyurethane foams. Their reinforced structure makes them ideal for automotive seats, furniture, and footwear, where durability and comfort are essential. They also enhance insulation in appliances and construction materials. Additionally, polymer polyols improve processability in spray coatings and adhesives, offering a balance of flexibility and strength.

Polyols are generally safe when handled properly, but precautions are necessary. Uncured polyols may irritate skin or eyes, requiring protective gear. Inhalation of vapors during processing should be avoided with adequate ventilation. Most polyols are non-toxic post-cure, complying with regulations like REACH and FDA standards for food-contact applications. Always follow safety data sheets (SDS) and manufacturer guidelines for storage, handling, and disposal.

(Polyol/Polyether Polyol/Polymer Polyol /Hot Polyol/ Polyol in Good )