Overview of Powder Anionic Polyacrylamide Uesd for Metallurgical

Anionic surfactants are a class of surface-active agents characterized by a negatively charged hydrophilic head group when dissolved in water. This charge arises from the presence of a sulfate, sulfonate, phosphate, or carboxylate group. They are among the most widely used surfactants due to their effective cleaning properties, foaming capacity, and broad compatibility with other formulation ingredients. Anionic surfactants find extensive application across industries, including personal care, household cleaning, textiles, and industrial processes.

Features of Powder Anionic Polyacrylamide Uesd for Metallurgical

-

Negative Charge: The anionic head group imparts water solubility and enables interaction with positively charged surfaces or particles.

-

Detergency: Exceptional at removing dirt, grease, and oils due to their strong polarity and ability to penetrate and disrupt these substances.

-

Foaming Properties: Many anionic surfactants generate stable and abundant foam, making them ideal for applications where lather is desired.

-

Cost-Effectiveness: They are often less expensive than nonionic, cationic, or amphoteric surfactants due to the abundance of raw materials and established production processes.

-

Compatibility: Can be combined with other surfactants to enhance performance or adjust properties, although care must be taken to avoid precipitation or incompatibility issues.

-

Environmental Considerations: Some anionic surfactants may pose environmental concerns due to their persistence or toxicity; however, biodegradable options are available.

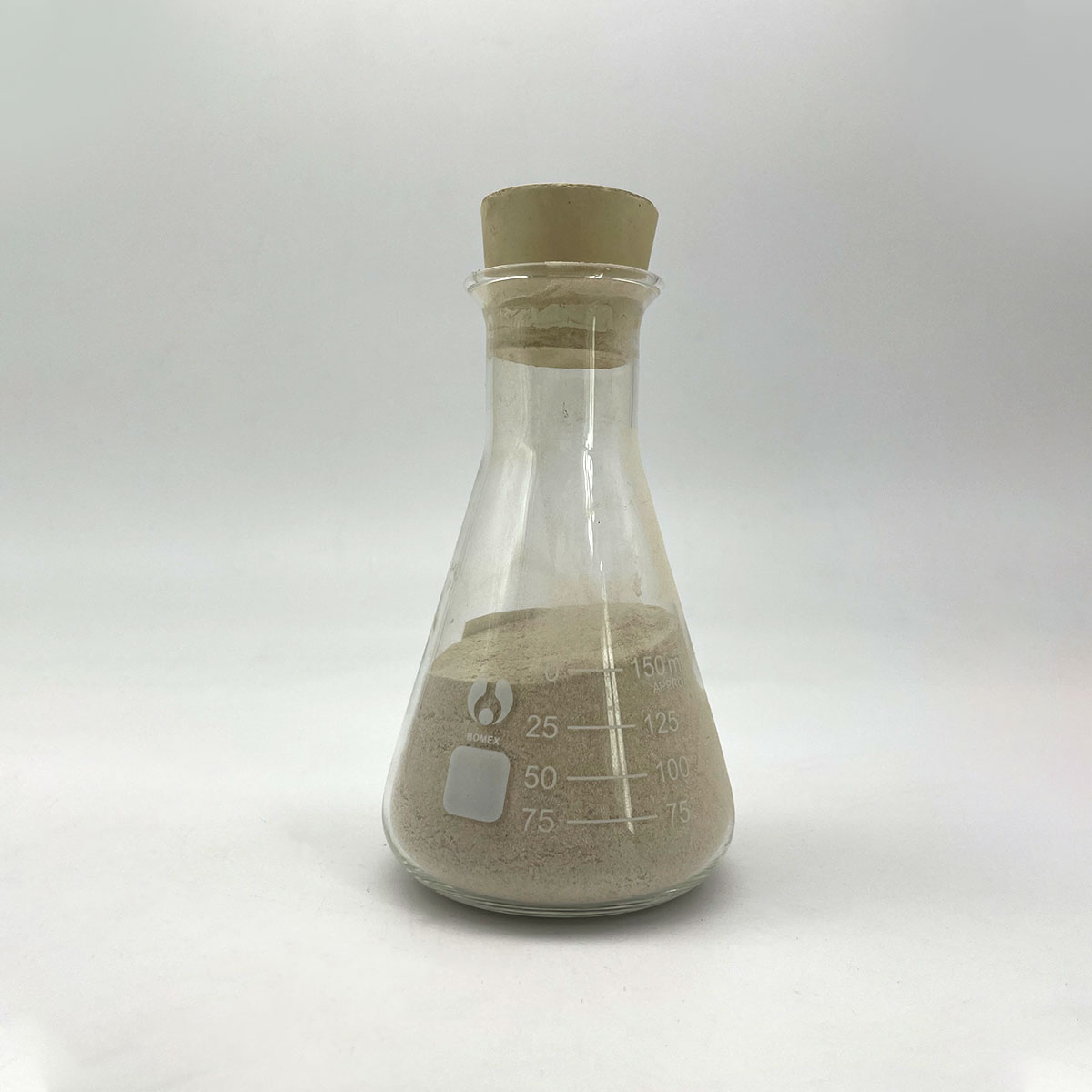

(Powder Anionic Polyacrylamide Uesd for Metallurgical)

Specification of Powder Anionic Polyacrylamide Uesd for Metallurgical

Powder Anionic Polyacrylamide (APAM) is a high-molecular-weight polymer widely utilized in metallurgical processes for solid-liquid separation, wastewater treatment, and sludge dewatering. Its anionic nature permits it to serve as a reliable flocculant, improving the effectiveness of sedimentation, purification, and clarification in metal ore processing, tailings management, and smelting procedures. Below are the vital specs and attributes of this product:

** Appearance **: White or off-white free-flowing powder.

** Molecular Weight **: Normally varies in between 10– 25 million Daltons, optimized to stabilize thickness and flocculation performance.

** Ionic Level **: 10%– 40% anionic fee density, adjustable to suit certain ore types and procedure demands.

** Solubility **: Liquifies quickly in water (≤ 60 mins) to form a viscous solution, making sure quick integration into procedure streams.

** Residual Monomer **: ≤ 0.05% acrylamide material, meeting worldwide security and environmental requirements.

** Strong Web content **: ≥ 90%, ensuring high pureness and very little inert additives.

** Particle Dimension **: 80– 100 mesh for regular dispersion and dissolution.

** pH Tolerance **: Stable efficiency across a broad pH variety (5– 14), suitable for alkaline or acidic metallurgical effluents.

** Thickness **: 3.0– 7.0 mPa · s (0.1% aqueous remedy at 25 ° C), offering ideal connecting and cost neutralization.

** Applications in Metallurgy **:.

– ** Ore Handling **: Accumulations great bits in mineral slurry, enhancing filtering rates and steel recovery.

– ** Tailings Dewatering **: Reduces water content in tailings, assisting in dry stacking and minimizing environmental threats.

– ** Smelting Wastewater Treatment **: Eliminates suspended solids and hefty metals from acidic or alkaline wastewater.

– ** Sludge Enlarging **: Enhances sludge compaction in clarifiers, minimizing disposal costs.

** Usage Guidelines **:.

1. Prepare a 0.1%– 0.3% service by progressively sprinkling the powder into perturbed water.

2. Adjust dose (0.1– 5 ppm) based upon slurry concentration, fragment dimension, and system pH.

3. Stay clear of extreme shear during mixing to stop polymer chain destruction.

** Packaging **: 25 kg moisture-proof kraft paper bags with polyethylene liners. Store in a great, dry location far from straight sunlight. Shelf life is 24 months when unopened.

This product is non-toxic, non-corrosive, and follow ISO 9001 and ISO 14001 requirements. It boosts process efficiency, minimizes water intake, and sustains sustainable metallurgical operations.

(Powder Anionic Polyacrylamide Uesd for Metallurgical)

Applications of Powder Anionic Polyacrylamide Uesd for Metallurgical

Powder Anionic Polyacrylamide (APAM) is a high-performance water-soluble polymer commonly used in metallurgical procedures as a result of its extraordinary flocculation, sedimentation, and splitting up homes. Its anionic charge and molecular structure make it extremely efficient in dealing with wastewater, taking care of tailings, and boosting mineral recuperation. Below are vital applications of APAM in the metallurgical industry:

** Mineral Handling and Ore Beneficiation **: APAM is critical in solid-liquid separation throughout ore processing. It speeds up the settling of great bits in slurries, improving clarification and purification performance. This is essential in procedures like seeping, flotation, and magnetic separation, where fast sedimentation makes certain higher healing prices of important metals and lowers water consumption.

** Wastewater Treatment **: Metallurgical operations generate big volumes of wastewater including heavy metals, suspended solids, and poisonous deposits. APAM aggregates these contaminants right into larger flocs, allowing easy elimination using sedimentation or filtration. This treated water can be reused, minimizing freshwater intake and making certain conformity with environmental regulations.

** Tailings Administration **: APAM improves dewatering of tailings– the waste by-products of ore processing. By binding fine bits, it decreases tailings slurry quantity, minimizes storage space footprint, and boosts dam security. It also assists in water recuperation from tailings, promoting sustainable resource usage.

** Smelting and Refining **: Throughout smelting, APAM is made use of in gas scrubbing systems to record dirt and particulates from exhaust gases. It also deals with acidic or alkaline effluents produced throughout metal refining, counteracting hazardous components and stopping environmental contamination.

** Dust Reductions **: In mining and material handling, APAM functions as a dust suppressant. When splashed on ore stacks or transportation courses, it forms a cohesive layer that binds dirt bits, lowering airborne air pollution and boosting workplace safety and security.

APAM provides advantages such as cost-effectiveness, low dose requirements, and flexibility to differing pH and temperature level problems. Its safe nature makes sure risk-free handling, while its performance sustains sustainable metallurgical methods. Ideal performance calls for dosage adjustments based upon ore type, particle size, and process specifics. By incorporating APAM, metallurgical procedures achieve greater performance, lowered ecological impact, and compliance with global standards for source effectiveness.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Powder Anionic Polyacrylamide Uesd for Metallurgical

**What is the primary use of Powder Anionic Polyacrylamide (APAM) in metallurgical processes?**

Powder Anionic Polyacrylamide is primarily used in metallurgy for solid-liquid separation, wastewater treatment, and sludge dewatering. It aids in aggregating fine particles and metal ions in mining effluents, tailings, and mineral processing wastewater, improving sedimentation, filtration efficiency, and water clarity. This enhances resource recovery, reduces environmental pollution, and supports compliance with discharge regulations.

**How does Powder Anionic Polyacrylamide work in metallurgical applications?**

APAM’s negatively charged polymer chains attract and bind to positively charged particles (e.g., metal hydroxides or mineral fines) via charge neutralization and bridging. This forms larger flocs that settle faster or are easily filtered, separating solids from liquids. Its high molecular weight ensures effective aggregation even at low dosages, optimizing process efficiency.

**What is the recommended dosage for Powder Anionic Polyacrylamide in metallurgical systems?**

Dosage varies based on wastewater composition, pH, and particle concentration. Typically, 0.1–5 mg/L is effective, but lab tests are critical for optimization. Overdosing can cause excessive viscosity, poor settling, or residual polymer issues. Gradual addition and proper mixing ensure uniform dispersion and maximal performance.

**Is Powder Anionic Polyacrylamide safe to handle in metallurgical plants?**

APAM is non-toxic but requires standard safety precautions. Avoid direct inhalation of powder or prolonged skin contact. Use PPE (gloves, masks) during handling. Dissolved solutions are low-risk, but spills should be cleaned promptly to prevent slips. Proper storage and disposal prevent environmental contamination.

**How should Powder Anionic Polyacrylamide be stored for metallurgical use?**

Store in a cool, dry, ventilated area away from moisture, heat, and direct sunlight. Keep containers tightly sealed to prevent clumping or degradation. Shelf life is up to two years under ideal conditions. Pre-dissolve the powder in water before use, ensuring agitation for even hydration and effectiveness.

(Powder Anionic Polyacrylamide Uesd for Metallurgical)