Overview of Redispersible Polymer Powder Rdp Vae

Polymer surfactants, also known as polymeric surfactants or amphiphilic polymers, are high-molecular-weight compounds that combine the properties of traditional low-molecular-weight surfactants with the unique features of polymers. Unlike small molecule surfactants, polymer surfactants offer enhanced stability, improved solubility, and the ability to form more complex structures such as micelles, hydrogels, and vesicles. These macromolecules find applications across a wide range of industries due to their tailored structures and tunable properties, which allow for precise control over interfacial behavior and solution rheology.

Features of Redispersible Polymer Powder Rdp Vae

-

Molecular Weight and Structure: With a much higher molecular weight, polymer surfactants offer enhanced stability in harsh conditions and over prolonged periods compared to small molecule surfactants.

-

Tunability: The structure of polymer surfactants can be precisely engineered to include different functional groups, monomer sequences, and architectures, allowing for specific interactions and properties.

-

Multifunctionality: Apart from surface activity, they can also provide additional functionalities like thickening, rheology modification, and controlled release capabilities.

-

Self-Assembly: Capable of forming sophisticated self-assembled structures like micelles, hydrogels, and vesicles, which can encapsulate or release active ingredients in a controlled manner.

-

Environmental Compatibility: Many polymer surfactants are designed to be biodegradable and less toxic, making them suitable for eco-friendly applications.

-

Temperature and pH Responsiveness: Some polymer surfactants exhibit responsive behavior to changes in temperature or pH, enabling stimuli-responsive systems.

(Redispersible Polymer Powder Rdp Vae )

Specification of Redispersible Polymer Powder Rdp Vae

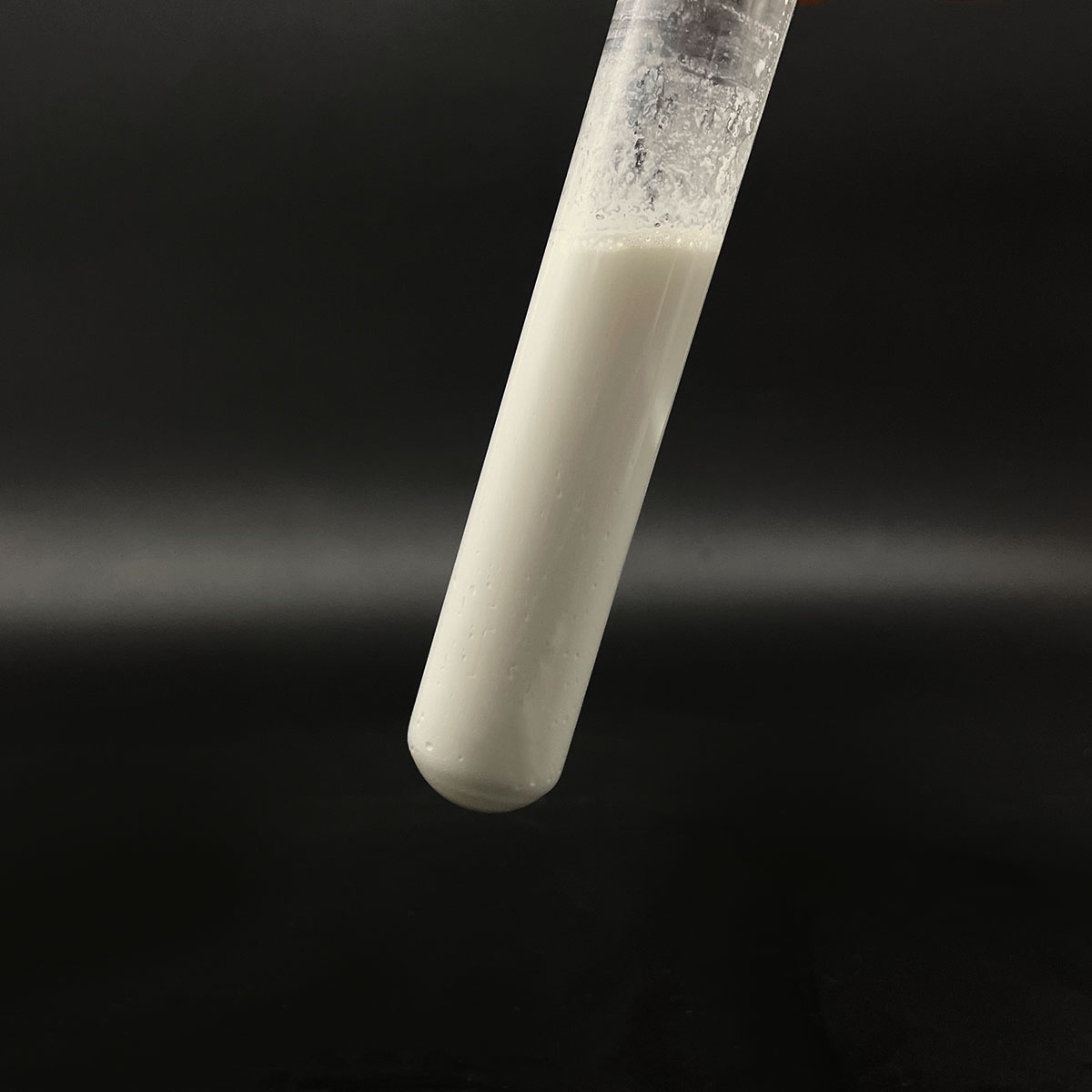

Redispersible Polymer Powder RDP VAE is a free-flowing white powder made from vinyl acetate-ethylene copolymer. It dissolves easily in water to form a stable emulsion. This powder enhances the performance of construction materials. It improves adhesion, flexibility, and water resistance in cement-based products. The powder works in dry-mix mortars like tile adhesives, self-leveling compounds, and exterior insulation systems.

The product has a high polymer content, typically between 98% to 99%. Moisture content stays below 1.5% to prevent clumping. The pH level ranges from 6.0 to 8.0, ensuring compatibility with other materials. Particle size is controlled between 80 to 120 microns for even dispersion. It meets international standards for safety and environmental regulations.

Adding RDP VAE to mortars increases cohesion and reduces cracking. It helps mortars withstand temperature changes and mechanical stress. The powder improves workability, allowing easier application. It extends open time for adjustments during installation. The polymer film formed after curing resists water penetration. This makes it suitable for wet areas like bathrooms or outdoor surfaces.

RDP VAE is compatible with common additives like cellulose ethers and defoamers. It works in both thick-bed and thin-bed mortar applications. Storage requires a cool, dry place to maintain stability. The shelf life is up to 12 months if unopened. Once mixed, the product should be used promptly to avoid setting issues.

The powder is eco-friendly, containing no harmful solvents. It reduces dust formation during mixing. Low emission levels make it safe for indoor use. Builders and manufacturers prefer it for consistent quality and reliability. Proper dosing ensures optimal performance without compromising material strength. Testing under different conditions confirms its durability and long-term effectiveness.

Packaging options include 25-kilogram paper bags or bulk containers. Custom orders are available for large-scale projects. Technical support is provided to assist with formulation adjustments. The product undergoes strict quality checks to meet industry demands.

(Redispersible Polymer Powder Rdp Vae )

Applications of Redispersible Polymer Powder Rdp Vae

Redispersible Polymer Powder (RDP VAE) is extensively used in building and construction materials. It enhances performance in items like ceramic tile adhesives, cement-based mortars, and self-leveling substances. Building contractors add RDP VAE to mixes due to the fact that it improves bond, adaptability, and water resistance. These characteristics help materials stick far better to surfaces and last much longer under tension.

In ceramic tile adhesives, RDP VAE makes the bond stronger. It protects against tiles from sliding or breaking. This serves in wet areas like restrooms. The powder also reduces the risk of water damage. It maintains the sticky steady also when subjected to moisture.

Self-leveling flooring compounds make use of RDP VAE to spread smoothly. The powder ensures the mix dries out equally without shrinking. This develops flat surface areas prepared for floor covering. It also quickens drying out times. Employees end up jobs much faster without giving up high quality.

Outside insulation systems rely on RDP VAE for longevity. The powder aids insulation layers stay with wall surfaces. It withstands weather condition modifications like warmth or rain. This maintains structures energy-efficient year-round. Fractures are much less likely to create, decreasing upkeep costs.

Cement renders and plasters gain from RDP VAE too. The powder adds adaptability to breakable concrete blends. Wall surfaces remain crack-free as temperatures change. It likewise improves workability. Building contractors apply the product efficiently, saving effort and time.

RDP VAE enhances gypsum-based products. Joint fillers and skim coats end up being extra cohesive. The powder prevents dusting and surface issues. Finished wall surfaces look cleaner and hold paint better.

Paints and coatings use RDP VAE for better movie formation. The powder assists colors stay with harsh surfaces. It also reduces peeling off or flaking over time. This is perfect for outside wall surfaces exposed to extreme problems.

RDP VAE operates in specialized applications like textile printing. It binds pigments to materials without fading. Paper layers come to be smoother and extra tear-resistant. The powder’s flexibility makes it important across industries. Its function in improving product high quality keeps it in high need.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Redispersible Polymer Powder Rdp Vae

Redispersible Polymer Powder (RDP VAE) is a key material in construction products. People often ask questions about it. Here are five common ones. What is RDP VAE? RDP VAE is a white powder made from vinyl acetate-ethylene copolymer. It dissolves in water again when mixed. It improves adhesion, flexibility, and workability in materials like tile adhesives or wall putty.

Why use RDP VAE in construction? It makes products better. Adding it to cement or gypsum increases bond strength. It stops cracks from forming. It helps materials resist water and last longer. Builders like it because it makes surfaces smoother and easier to handle.

What are the main benefits? RDP VAE has many advantages. It makes mixes stick better to different surfaces. It reduces the chance of coatings peeling off. It lets materials bend slightly without breaking. This is good for places that get hot or cold often. It also helps products stay usable longer by slowing down drying.

How is RDP VAE different from other polymers? It works differently. Regular polymers might not redisperse well after drying. RDP VAE keeps its properties even after getting wet again. This makes it more reliable in changing weather. It is safer to handle than liquid polymers. Powder is easier to store and transport without spills.

How should RDP VAE be stored? Keep it dry and cool. Moisture makes the powder clump. Use sealed bags and store them off the ground. Avoid direct sunlight. High heat can damage the powder’s quality. Check the expiration date. Use older stock first to keep it fresh.

(Redispersible Polymer Powder Rdp Vae )