Overview of Used in The Oil Field Npam Powder Glyoxal Nonionic Polyacrylamide

Nonionic surfactants are a class of surface-active agents that do not carry an electrical charge in aqueous solutions, distinguishing them from ionic surfactants like cationics and anionics. They are composed of a hydrophilic (water-loving) head group and a hydrophobic (oil-loving) tail, which allows them to reduce surface tension between fluids and facilitate interactions between substances that are normally immiscible. Their neutrality makes them stable over a wide pH range and compatible with other types of surfactants, making them highly versatile in numerous applications.

Features of Used in The Oil Field Npam Powder Glyoxal Nonionic Polyacrylamide

-

Neutral Charge: Lack of charge leads to compatibility with both anionic and cationic substances, reducing the risk of precipitation or instability in formulations.

-

Wide pH Stability: Function effectively across a broad pH range, making them suitable for diverse chemical environments.

-

Solubility: Readily soluble in both water and organic solvents, enhancing their utility in cleaning, emulsification, and dispersion processes.

-

Low Foam Profile: Many nonionic surfactants generate less foam compared to their ionic counterparts, beneficial in applications where excessive foam is undesirable.

-

Wetting and Spreading: Excellent at reducing surface tension, promoting wetting and spreading of liquids on surfaces, improving cleaning and coating processes.

-

Emulsification: Efficiently stabilize oil-in-water or water-in-oil emulsions, depending on their structure, which is crucial in formulations like cosmetics, agrochemicals, and food products.

(Used in The Oil Field Npam Powder Glyoxal Nonionic Polyacrylamide)

Specification of Used in The Oil Field Npam Powder Glyoxal Nonionic Polyacrylamide

NPAM Powder Glyoxal Nonionic Polyacrylamide is a high-performance chemical additive designed for oil area applications, providing enhanced thickness, stability, and liquid control. This crosslinked polymer is manufactured by reacting nonionic polyacrylamide with glyoxal, producing a product with delayed solubility and customized efficiency in tough atmospheres. Below are its vital specs and features:

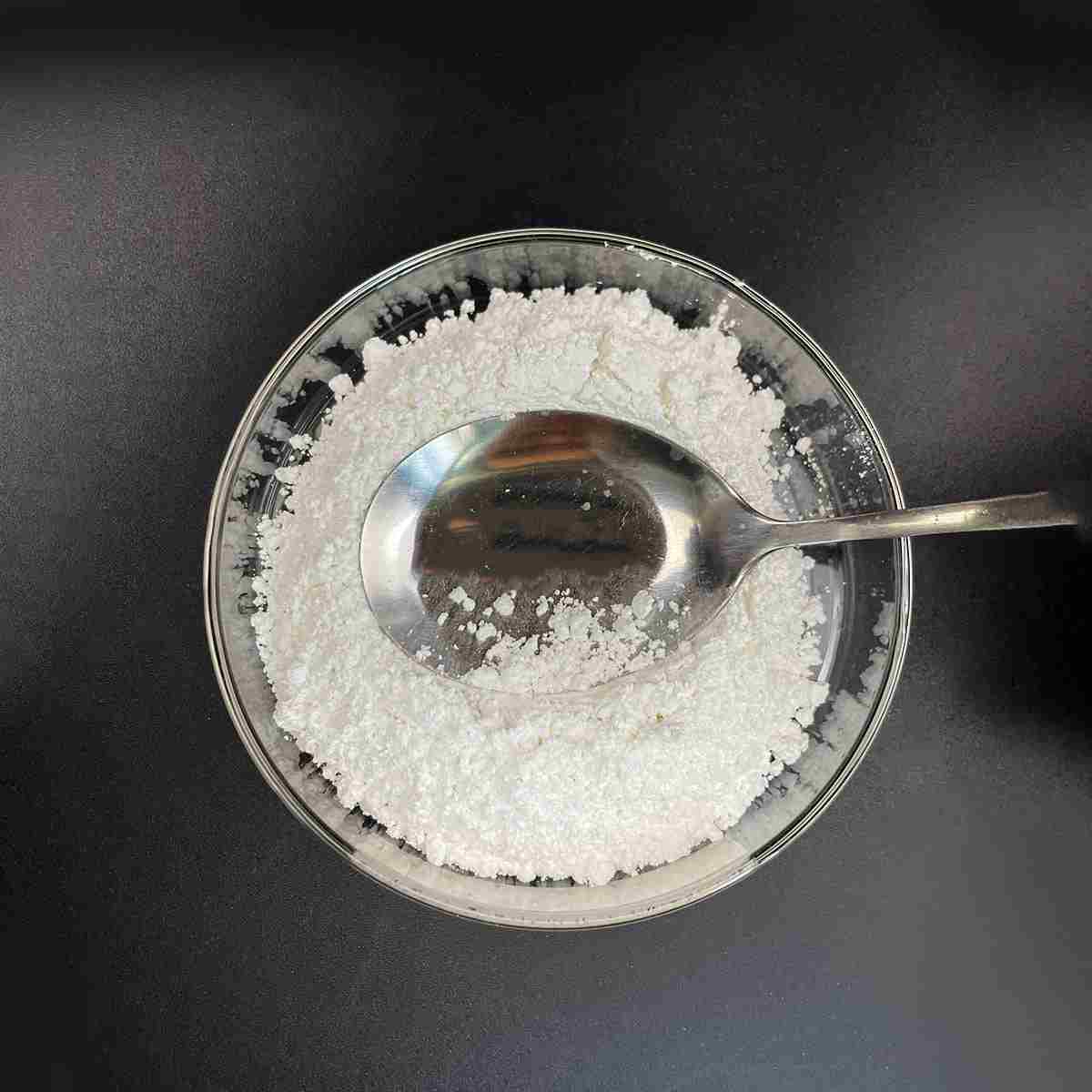

** Appearance **: White or beige free-flowing powder, making sure very easy handling and consistent dispersion.

** Chemical Structure **: Nonionic polyacrylamide crosslinked with glyoxal. The polymer has a high molecular weight varying between 5– 12 million Daltons, optimizing its thickening and friction-reduction properties.

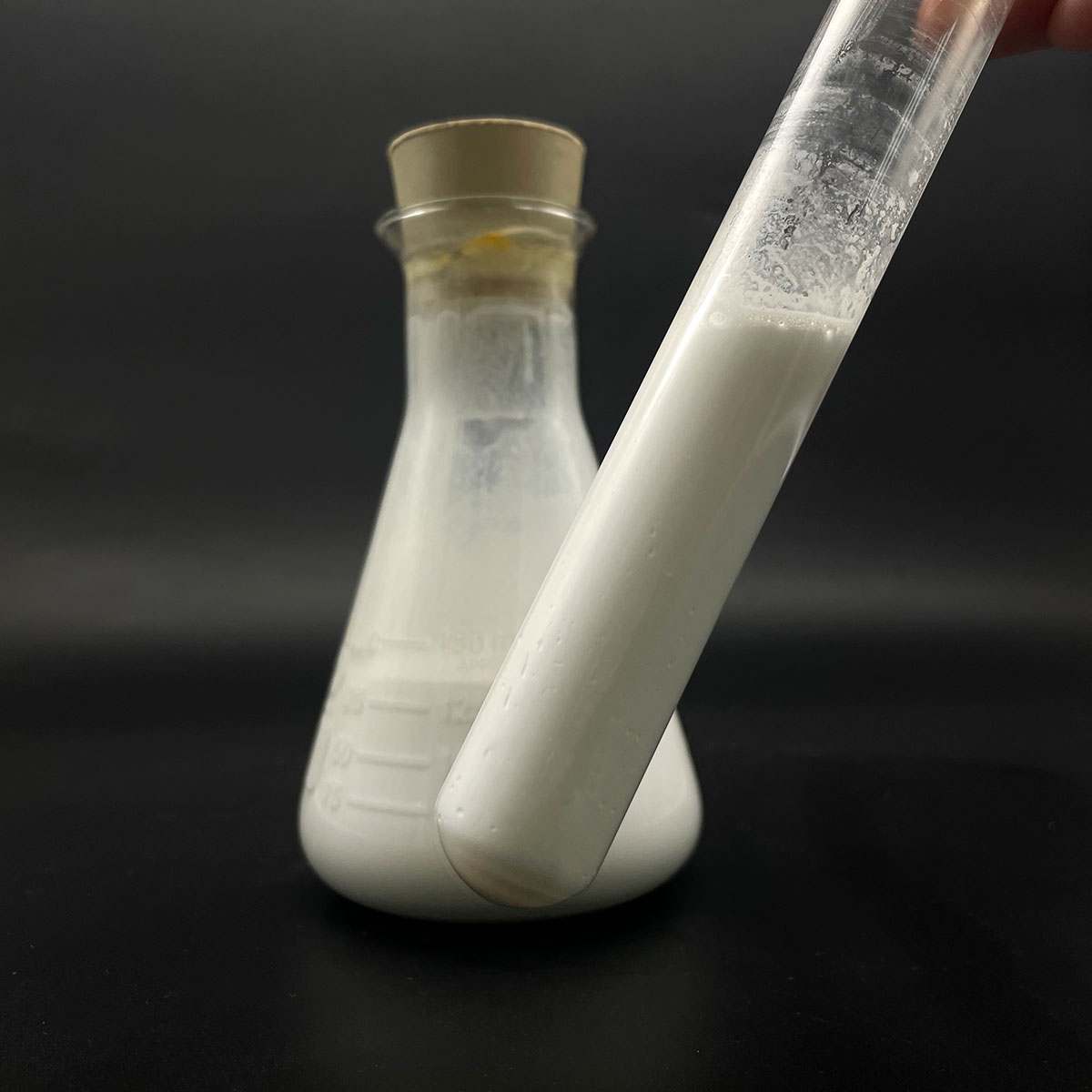

** Solubility **: Displays managed dissolution in water, slowly moisturizing to form a viscous solution. This delayed solubility is perfect for sustained efficiency in deep wellbore conditions.

** Thickness **: Supplies high viscosity (normally 50– 150 mPa · s at 0.1% concentration in liquid solutions), boosting fluid bring capability and reducing rubbing in pipes.

** pH Stability **: Effective throughout a wide pH array (3– 10), making it ideal for acidic or alkaline downhole atmospheres.

** Applications **:.

– ** Drilling Liquids **: Reduces fluid loss, stabilizes boreholes, and enhances lubrication.

– ** Enhanced Oil Recuperation (EOR) **: Rises water viscosity in flooding procedures to displace trapped oil.

– ** Friction Reduction **: Decreases turbulence in hydraulic fracturing and fluid transport.

– ** Water Shutoff **: Seals high-permeability zones to reroute water circulation and boost sweep effectiveness.

** Dose **: Advised use ranges 0.05%– 0.3% by weight, depending upon particular well conditions and desired viscosity.

** Product packaging **: Supplied in 25 kg moisture-resistant woven bags with inner polyethylene linings to prevent clumping.

** Storage **: Store in a cool, completely dry, aerated area away from direct sunshine. Shelf life is up to 24 months when unopened.

** Safety **: Safe but needs basic PPE (handwear covers, masks) during dealing with to stay clear of breathing or skin contact. Dispose of according to local regulations.

NPAM Powder Glyoxal Nonionic Polyacrylamide is a versatile option for maximizing oil field operations, combining reliability with cost-efficiency sought after environments.

(Used in The Oil Field Npam Powder Glyoxal Nonionic Polyacrylamide)

Applications of Used in The Oil Field Npam Powder Glyoxal Nonionic Polyacrylamide

Nonionic Polyacrylamide (NPAM) powder treated with glyoxal is a functional chemical commonly made use of in the oil and gas sector due to its one-of-a-kind homes, consisting of high thickness, thermal security, and resistance to salinity. This polymer plays an essential function in enhancing functional performance and resolving obstacles in boring, manufacturing, and wastewater monitoring. Below are essential applications of glyoxal-modified nonionic polyacrylamide in oil area procedures:

** Drilling Fluid Additive **: NPAM-glyoxal powder is utilized in exploration liquids to improve viscosity and minimize fluid loss. It maintains borehole walls by forming a thin, impenetrable filter cake, stopping development damages and lessening water invasion. This makes certain smoother boring operations, lowers downtime, and decreases the threat of wellbore collapse in sensitive formations.

** Boosted Oil Recovery (EOR)**: In water flooding or polymer flooding, NPAM-glyoxal acts as a wheelchair control representative. Its high molecular weight raises the viscosity of injected water, improving move effectiveness and displacing trapped oil from reservoirs. The glyoxal therapy boosts its thermal security, making it reliable in high-temperature reservoirs where standard polymers deteriorate.

** Generated Water Treatment **: Oilfield-produced water consists of emulsified oils and put on hold solids. NPAM-glyoxal functions as a flocculant, accumulating great particles and oil droplets for much easier separation. This ensures compliance with ecological discharge requirements and allows water reuse, decreasing freshwater intake.

** Hydraulic Fracturing **: As a friction reducer and proppant service provider, NPAM-glyoxal enhances the performance of fracturing fluids. It lowers pressure losses throughout shot, allowing deeper infiltration right into fractures. The crosslinked framework from glyoxal enhances gel toughness, making sure proppants continue to be suspended to keep fracture conductivity.

** Well Cementing **: In concrete slurries, NPAM-glyoxal stops fluid loss throughout sealing operations. It stabilizes the slurry’s rheology, making certain appropriate zonal seclusion and reducing gas migration dangers. This boosts the durability and stability of well coverings.

** Advantages **: The nonionic nature of NPAM-glyoxal ensures compatibility with various other additives and minimizes interactions with divalent ions in difficult brine or high-salinity atmospheres. Its customized framework uses prolonged stability under rough conditions, lowering dosage demands and operational costs.

In summary, glyoxal-treated nonionic polyacrylamide powder is a multifunctional option for oil area challenges, enhancing boring, manufacturing, and environmental administration. Its capability to carry out under severe temperatures, salinity, and mechanical tension makes it essential for modern-day hydrocarbon extraction procedures.

Company Profile

SurfactantChina is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality surfactant and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality surfactant and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Used in The Oil Field Npam Powder Glyoxal Nonionic Polyacrylamide

What are the primary applications of NPAM Powder Glyoxal Nonionic Polyacrylamide in oil fields? NPAM Powder Glyoxal Nonionic Polyacrylamide is primarily used in drilling fluids, enhanced oil recovery (EOR), and well stimulation. It acts as a viscosifier, fluid loss controller, and friction reducer. Its crosslinked structure, enhanced by glyoxal, helps stabilize boreholes, improve mud efficiency, and increase oil displacement in reservoirs, especially in high-temperature or high-salinity environments.

How does Glyoxal enhance the performance of Nonionic Polyacrylamide? Glyoxal modifies Nonionic Polyacrylamide by creating temporary crosslinks within the polymer chains. This boosts thermal stability (up to 120°C/248°F) and salt tolerance, allowing the polymer to maintain viscosity and effectiveness in harsh downhole conditions. The crosslinks dissolve gradually, enabling controlled fluid loss prevention and extended performance during drilling or fracturing operations.

What is the recommended dosage for optimal performance? The typical dosage ranges from 0.1% to 0.5% by weight of the drilling fluid or solution, depending on well conditions. For high-temperature or high-salinity environments, higher concentrations (up to 0.5%) may be required. Always conduct lab tests to tailor dosage to specific well parameters like temperature, pressure, and mineral content.

Are there any safety or environmental considerations when using this product? The powder is non-toxic but requires careful handling to avoid inhalation or skin contact. Use PPE like gloves and masks. Spills should be contained to prevent environmental contamination. While the product is biodegradable, large-scale releases into water systems should be avoided. Follow local regulations for disposal.

How should NPAM Powder Glyoxal Nonionic Polyacrylamide be stored, and what is its shelf life? Store in a cool, dry place away from moisture and direct sunlight. Keep packaging sealed to prevent clumping. Shelf life is 12–24 months when stored properly. Avoid extreme temperatures (above 40°C/104°F or below freezing) to maintain efficacy. Use airtight containers for long-term storage.

(Used in The Oil Field Npam Powder Glyoxal Nonionic Polyacrylamide)